Round heating film is a cutting-edge solution for modern heating needs, providing efficient and versatile heating for various applications. It is an increasingly popular choice, particularly in electronics, due to its flexibility, ease of use, and durability. This blog will explore everything you need to know about round heating film, from its benefits to its applications and customization options. Whether you’re in electronics or looking for an energy-efficient heating method, round heating film may be the solution you need.

What is Round Heating Film?

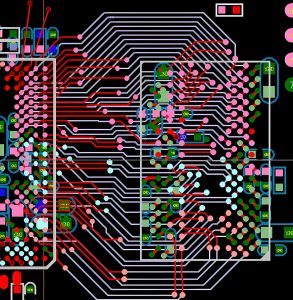

Round heating film is a thin, flexible film that produces heat when an electric current passes through it. It is typically made of a conductive material that allows electricity to generate heat across the surface of the film. Unlike traditional heating elements, which can be bulky or rigid, round heating films are lightweight and adaptable. This makes them ideal for use in a variety of industries, including electronics, automotive, and medical applications. The ability to provide uniform heating while maintaining flexibility is a key advantage of this technology.

What Are the Benefits of Using Round Heating Film in Electronics?

Round heating film offers several benefits when used in electronics. One major advantage is its ability to generate heat without taking up much space. In many electronic devices, space is limited, so using round heating film can help manage heat dissipation in compact designs. Additionally, it provides a more uniform heat distribution compared to traditional heating elements, reducing the risk of overheating and improving device longevity. Moreover, round heating film operates efficiently, contributing to energy savings and overall performance.

Another benefit is its flexibility. Round heating films can be easily shaped to fit the contours of different components, allowing for more innovative and custom designs. For electronics manufacturers, this adaptability means they can integrate heating solutions more seamlessly into their products, offering better thermal management and reliability.

How to Choose the Right Round Heating Film for Your Needs?

When selecting the right round heating film for your application, itās important to consider factors such as temperature range, size, and material composition. Different types of round heating films are designed for specific purposes, so understanding the requirements of your project is essential.

For example, if your device requires high temperatures for short durations, a round heating film with higher power density may be ideal. On the other hand, if the heating needs to be more gradual or lower in temperature, films with different materials or configurations might be better suited. Itās also important to assess the filmās durability and resistance to wear over time, especially for products that will be exposed to frequent use or extreme conditions.

How Does Round Heating Film Compare to Traditional Heating Methods?

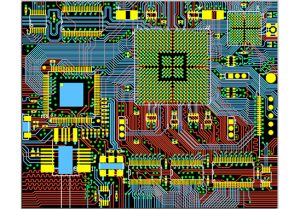

How does round heating film stack up against traditional heating methods? The primary difference lies in its design and efficiency. Traditional heating methods, such as metal coils or ceramic elements, are often bulky and rigid, requiring more space and sometimes more energy to function. In contrast, round heating film is thin, flexible, and can be applied directly to surfaces, allowing for more precise and efficient heating.

Moreover, traditional heating methods can sometimes produce uneven heat, leading to inefficiencies. Round heating films, however, offer uniform heat distribution across their surface, making them more reliable and energy-efficient. While traditional heating elements are still widely used, the growing demand for smaller, more efficient heating solutions makes round heating film an increasingly attractive choice.

What Are the Common Applications for Round Heating Film?

Round heating film has a wide range of applications across various industries. In electronics, it’s used for thermal management in devices such as smartphones, laptops, and LED displays. Itās also commonly found in automotive heating systems, such as heated seats and defrosting systems. Round heating film is even used in medical devices for applications that require controlled heating, like therapeutic equipment or wearable technology.

In addition to these, round heating films are also used in consumer products like heated blankets and jackets, as well as in industrial machinery for applications that require localized heating. The versatility of round heating film makes it suitable for any application where compact, efficient, and reliable heating is required.

Can Round Heating Film Be Customized for Specific Uses?

Yes, round heating film can be easily customized to suit specific needs. Manufacturers can adjust the size, shape, and temperature capabilities of the heating film to match the requirements of different devices or applications. This flexibility makes it a valuable choice for industries where standard heating solutions may not fit.

For example, in the electronics industry, custom round heating films can be designed to fit specific components or layouts, ensuring that the heat is distributed exactly where itās needed. In other sectors, such as automotive or medical fields, customization allows for the creation of specialized heating solutions that are both effective and efficient.

How Durable is Round Heating Film for Long-Term Use?

Round heating films are known for their durability, especially when compared to traditional heating methods. Because they are made from flexible, conductive materials, they are less likely to break or wear out over time. The thin design of the film also makes it resistant to damage from external forces such as pressure or impact, which can be a concern with more rigid heating elements.

Additionally, round heating films are designed to withstand high temperatures and frequent use, making them a reliable option for long-term applications. Whether used in consumer electronics or industrial equipment, round heating films maintain their performance and efficiency over time, offering a great return on investment.

Why Choose Round Heating Film?

Choosing round heating film offers several advantages that make it an excellent option for many applications. Its flexibility, compact design, and energy efficiency set it apart from traditional heating solutions. Whether you’re looking for a more efficient way to manage heat in electronics or need a customizable heating solution for a specialized product, round heating film offers a solution that can meet your needs. Best Technology delivers top-notch round heating film solutions with efficiency and precision. Feel free to contact us at sales@bestpcbs.com for any doubts or queries you might have.

Moreover, round heating film is adaptable, allowing for integration into a wide range of devices and products. Its uniform heat distribution and long-lasting durability make it a reliable and cost-effective option. Overall, round heating film represents the future of heating technology, providing businesses and consumers alike with a smarter way to manage heat.

Round heating film is proving to be an essential part of the modern heating landscape, offering efficiency, adaptability, and durability for a variety of applications. Whether you’re designing an electronic device, a medical product, or even an automotive system, round heating film provides a practical and effective heating solution. By understanding its benefits, how to choose the right film, and its potential applications, you can make an informed decision for your heating needs. If you’re seeking a high-performance, customizable, and energy-efficient heating solution, round heating film is worth considering.