Silver is widely used in printed circuit boards (PCBs) for its excellent conductivity and thermal properties. A common concern of manufacturers is whether silver will oxidize over time, which may affect the performance of the PCB. And how should it be treated after oxidation? How should it be stored during use, etc.

How to remove oxidation from PCB?

The methods for removing oxides from PCBs mainly include physical cleaning, chemical cleaning, and mechanical polishing.

1. âPhysical cleaningâ:

Use alcohol or diluent to gently wipe the oxidized part until the oxide is removed. This method is suitable for removing the surface oxide layer, but it is not suitable for situations where the metal surface circuit has been damaged.

2. âChemical cleaningâ:

Use specific cleaning agents such as deionized water, isopropyl alcohol, acetone, etc. to effectively remove residues and contamination.

In addition, cleaning and corrosion using acidic solutions or oxidants is also an effective chemical method, but it must be used with caution to avoid damage to the PCB board and other components.

3. âMechanical polishingâ:

Use fine sandpaper or abrasive cloth to carefully polish the oxidized area to restore the conductivity of the metal. This method is suitable for removing thicker oxide layers, but you need to control the strength to avoid damaging the pad surface.

Before any cleaning and repair, be sure to disconnect the PCB power supply to ensure safety. For cases where oxidation has damaged the metal surface circuit, conductive paint needs to be used for repair, but be aware that excessive use of conductive paint may damage the circuit board. In addition, for unused PCBs, they should be stored in sealed bags or protective agents and checked regularly to ensure that they are not oxidized again.

Is silver oxidation permanent?

Silver oxidation is not permanent. â

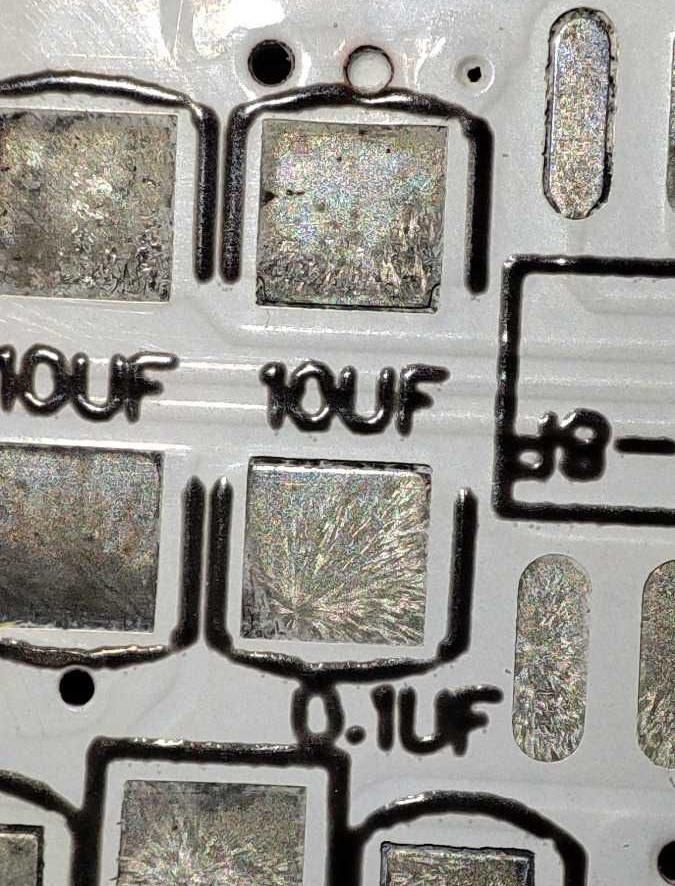

Silver oxidation is caused by the reaction of silver with chemicals such as oxygen and sulfur in the air, resulting in a black silver sulfide film on the silver surface. This oxidation reaction is one of the main reasons for the blackening of PCBs.

However, silver oxidation is not permanent, because the oxide layer can be removed by cleaning and maintenance to restore the gloss of the PCB surface. For example, regular use of professional PCB cleaners or soaking the PCB in diluted detergent water, then gently scrubbing it with a soft brush, and finally rinsing it with clean water and drying it can effectively remove the oxide layer.

In addition, avoiding contact with chemicals, keeping dry, regularly checking and properly storing PCBs are also effective ways to prevent oxidation.

Therefore, although silver oxidation is inevitable, the rate of oxidation can be slowed down through proper care and maintenance.

What is the best way to Deoxidize silver?

The best way to remove silver oxide from PCBs is to use chemical stripping, which involves using a specific chemical solution to treat the silver plating so that it dissolves in the solution to achieve the purpose of removing the oxide.

The effectiveness of this method depends on the selection of appropriate chemical formulas and operating conditions to ensure that the silver layer can be completely stripped while avoiding corrosion to the base metal.

In chemical stripping, different formulas can be used to achieve the removal of the silver layer. For example, one formula includes a mixture of concentrated sulfuric acid and concentrated nitric acid, which is used at a temperature of 80°C until the silver layer is completely stripped.

Another formula includes a mixture of sulfuric acid, nitric acid, silver chloride and potassium cyanide, which is also used at a temperature of 80°C. These formulas need to be selected according to actual conditions, and attention should be paid to safety measures during operation to prevent corrosion of the base metal.

In addition, for the oxidation problem of PCB gold fingers, although it is not exactly the same as the method of removing silver oxide, some cleaning methods are provided, such as using erasers, alcohol cleaning, decontamination paste cleaning, scrubbing board grinding and electroplating treatment, which are also suitable for treating silver oxide, especially when the oxide is relatively mild.

In summary, the best way to remove PCB silver oxide is chemical stripping, which is achieved by selecting appropriate chemical solutions and operating conditions. For more serious oxidation situations, it may be necessary to combine physical and chemical methods for cleaning.

How do you save silver from oxidation?

The methods to prevent PCB silver from oxidation mainly include the following points:

- Reasonable storage and packaging â: During storage and transportation, PCBs should be stored in a dry, ventilated, dust-free environment to avoid moisture and corrosion. Use appropriate packaging materials, such as moisture-proof bags, foam boxes, etc., to ensure the integrity and quality of the PCB.

- âSurface treatment â: During the PCB surface treatment process, surface treatment methods such as gold plating and tin plating can be used to prevent oxidation.

- Use anti-oxidation coating â: Anti-oxidation coating is an efficient and reliable method to prevent PCB oxidation. It can form a strong, corrosion-resistant protective layer on the surface of the PCB, effectively preventing the PCB from being damaged by oxidation.

- Reduce contact with air and moistureâ: Make sure the gold fingers are stored in a dry environment and avoid long-term exposure or immersion in water.

- âUse a protective coatingâ: Applying a protective coating on the gold fingers can help prevent oxidation. This can be done using a variety of materials, such as nickel, palladium, or a thin layer of metalâ.

- âRegular cleaning and inspectionâ: Regular cleaning of the gold fingers can also help prevent oxidation. This is done using a soft brush and a cleaning solution specifically designed for PCBsâ. Check the status of the gold fingers regularly, and clean and maintain them immediately if any signs of oxidation are foundâ.

What is the shelf life of immersion silver PCB?

The shelf life of immersion silver PCB is at least 12 months. âThis shelf life is determined under proper storage conditions, that is, in a sealed package, with a temperature controlled at 22 degrees plus or minus 4 degrees, and a relative humidity of less than 70%.

Once the circuit board is taken out for use, it must be soldered within 24 hours to ensure that its quality and performance are not affectedâ.

The thickness of immersion silver surface treatment is usually between 0.4 and 1 micron, and this treatment is widely used by chip manufacturers for baseline bonding, EMI shielding and metal dome contacts.

Its purpose is to provide a reliable surface treatment, ensuring that the PCB surface will not oxidize and maintain its electrical performance stability for a shelf life of 12 months according to the IPC J-STD-003 standard.

In addition, the shelf life of the circuit board is also affected by its surface treatment process. For example, the vacuum packaging storage period of immersion gold, electro-gold, and tin-spraying boards is 3 months, while the storage period after unpacking for OSP, immersion tin, and immersion silver boards is 48 hours, 72 hours, and 48 hours respectively.

This shows that immersion silver PCBs can maintain a long shelf life if they are not unpacked, but the soldering process needs to be completed as soon as possible before use to ensure their performance.

Conclusion:

Silver oxidation is a natural process, but it does not affect the performance of the PCB. The key to controlling silver oxidation is regular maintenance, proper storage, and quick action when rust occurs. It should be stored properly and coated with a protective coating when necessary.