Single sided rigid PCB manufacturer is a phrase more and more engineers and buyers are searching for. And for good reason. In today’s fast-moving electronics industry, having a reliable supplier that knows how to design, build, and deliver high-quality single-sided rigid PCBs means fewer delays and better performance. Whether you’re building LED lights, power supplies, or everyday electronics, you need a manufacturer who can deliver consistent quality with a fair price.

In this blog, we’ll write information from design to production, from cost to choosing a trustworthy partner. Best Technology is a leading single sided rigid PCB manufacturer. At Best Technology, quality isn’t a metric, it’s our survival imperative. We use the MES system to ensure the incoming material data is traceable. There are QR codes pasted on the package to trace the component data in the MES system. All the materials Best Technology uses are compliant with REACH, RoHS, and UL. Our factory is ISO9001, ISO13485, IATF16949 and AS9100D certified. Do you face technical hurdles in single sided rigid PCB design, prototyping, or assembly? Best Technology is on standby to resolve them. Just feel free to let us know via sales@bestpcbs.com.

How to design a single-sided PCB?

Single-sided PCB design starts with simplicity. Since there’s only one layer of copper, all components and routing stay on one side. That means space and layout matter more than ever.

To begin, use a good PCB design tool like Altium Designer, KiCad, or Eagle. The designer places components first, making sure spacing follows IPC guidelines. Then comes routing. Since there’s no second layer to cross over, you must plan carefully. Signal lines need to avoid overlaps, so often creative thinking is required.

Also, keep in mind power and ground paths. A wide trace for power lines avoids voltage drop. Thermal relief is another factor. It ensures the board evenly dissipates heat during soldering and prevents the soldering pad from being difficult to solder due to excessive heat dissipation caused by connecting a large area of copper foil.

Once finished, you’ll generate Gerber files. These files tell the single sided rigid PCB manufacturer exactly how to build your board.

How to manufacture a single-sided rigid PCB?

The single sided rigid PCB manufacturing process follows a clear and organized flow. Each step plays an important role in ensuring the final board works perfectly and looks clean. Here’s how it’s typically done in most factories:

Material Cutting

- Everything begins with a sheet of single-sided copper-clad laminate. The board is cut to the required size according to the production panel.

Cleaning and Drying

- Before any processing, the board surface must be free from dust and oil. It’s brushed clean, washed, and dried to ensure good adhesion for the next layers.

Drilling or Punching

- Holes for components or mounting are drilled using precise CNC machines or punched if the volume is large.

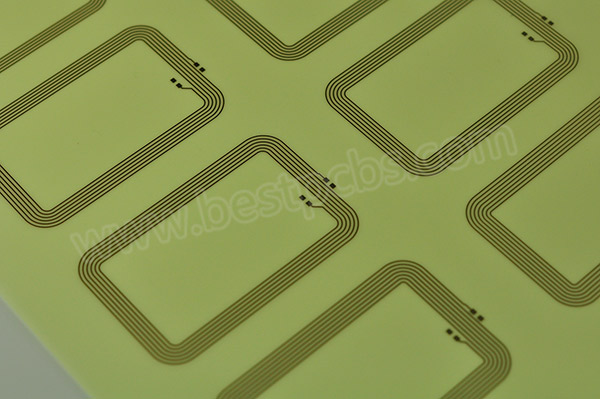

Printing or Laminating Circuit Pattern

- The circuit pattern is transferred to the copper layer. This can be done by screen-printing a resist ink or applying a dry film photoresist.

Curing and Inspection

- The printed resist is cured with heat or UV. Then, workers inspect for any errors or broken traces and repair them if needed.

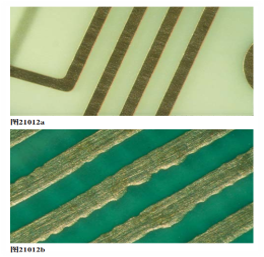

Etching

- The exposed copper areas are removed using chemical etching, leaving behind only the protected circuit pattern.

Stripping Resist and Drying

- Once etching is complete, the resist layer is removed, and the board is cleaned and dried again.

Solder Mask Application

- The green solder mask is screen-printed over the board to cover everything except the pads. This protects the traces and prevents short circuits during soldering.

UV Curing

- The solder mask is cured under UV light to harden it properly.

Silkscreen Marking

- Component labels, logos, or production marks are printed in white or yellow on the board using another screen-printing process.

Second UV Curing

- These printed marks are also UV cured to lock them in place.

Final Profile and Cutting

- Now the board is cut into its final shape using routing or punching, based on the product’s design.

Final Cleaning and Drying

- Another cleaning step ensures the board is free from debris before surface finishing.

Surface Finish

- Depending on customer needs, the surface is treated. This could be OSP (organic protective coating) or HASL (Hot Air Solder Leveling) for better solderability.

Electrical Testing

- Every board is tested to check for open circuits or shorts. This confirms the integrity of the copper traces.

Final Inspection and Packaging

- Before shipping, the boards are visually inspected again, counted, packed, and labeled.

Delivery

- Finally, the finished PCBs are sent out, ready to be assembled into your devices.

Every step above is important. Even the smallest issue in cleaning or printing can affect performance. That’s why choosing a skilled single sided rigid PCB manufacturer matters. They’ll get every step right, from the first cut to the final test. The process may seem basic, but precision at every step ensures a functional and long-lasting board.

How much does single sided rigid PCB manufacturing cost?

Pricing depends on several factors. Here’s what affects cost:

- Board size and shape: Larger or irregular shapes cost more.

- Material choice: In comparison to FR4, CEM-1, CEM-3 can save cost.

- Copper thickness: Heavier copper costs more but is used for power-heavy applications.

- Drill count and size: More holes mean longer machine time.

- Surface finish: ENIG costs more than HASL, for example.

- Quantity: Higher volumes bring unit cost down.

For bulk orders or repeat clients, the price becomes more competitive.

What are the disadvantages of single-sided PCB?

Single-sided PCBs are not always perfect. Still, their downsides are manageable with proper design. Let’s look at the few limitations:

- Limited routing space: Only one copper layer limits complexity.

- No crossover: Without vias or a second layer, designers must get creative with traces.

- Not ideal for high-speed circuits: Signal integrity can be harder to control.

But for simple electronics, lighting, or power modules, these downsides rarely cause problems. And that’s where a skilled single sided rigid PCB manufacturer helps — they know how to design within limits.

What are the advantages of single-side PCBs?

Now, the good part. Single-sided PCBs come with many benefits:

- Cost-effective: The process is quick and uses fewer materials.

- Easy to design and manufacture: With fewer layers, it’s easier to avoid errors.

- Reliable for simple circuits: Perfect for consumer electronics, sensors, and LED products.

- Faster lead time: Less production time means you get boards quicker.

- Great for prototyping: Want to test an idea fast? Single-sided boards are ideal.

When a single sided rigid PCB manufacturer knows the product’s purpose, they can optimize every part to reduce costs and increase output.

What makes a reliable single sided rigid PCB manufacturer stand out?

This is a question that smart buyers always ask. What separates one supplier from another?

- Experience: Look for at least 10 years in the industry.

- Certifications: ISO, UL, and RoHS compliance are a must.

- Fast prototyping: Can they deliver samples in under 5 days?

- Stable quality control: Ask about testing methods and inspection steps.

- Customer support: Are they responsive? Do they understand your needs?

- Transparent pricing: No hidden fees. Good suppliers are upfront about costs.

A top-tier single sided rigid PCB manufacturer doesn’t just build — they help you optimize, troubleshoot, and scale with confidence.

What is the best PCB manufacturer?

If you’re focused on single sided rigid PCB, the best partner is one who:

- Understands your product requirements.

- Offers fair pricing and fast delivery.

- Supports customization and technical improvement.

Best Technology, for example, is a strong candidate. With over 18 years in the business, we’ve helped 1700 global customers solve design issues, speed up production, and improve reliability. Our engineers don’t just follow a checklist — they engage, ask questions, and offer suggestions.

We get the competitive edge in small batch single-sided PCB design. There is no MOQ requirement for single sided copper PCB board prototype. Our single sided rigid PCBs are through automated optical inspection (AOI) and flying probe testing ensures high quality. If you’re searching for the best single sided rigid PCB manufacturer, a warm welcome to contact Best Technology at sales@bestpcbs.com for tailor single sided rigid PCB solutions.

Who is the largest single sided rigid PCB manufacturer in the world?

There are several big players in the PCB industry, especially across Asia. Companies like Best Technology, Tripod Technology, and Unimicron lead in overall volume.

When it comes to focused single sided rigid PCB manufacturing, many customers prefer working with companies that offer personalized service and fast response. For example, Best Technology in China could produce boards faster and offer more flexible MOQ policies. We offer 72-hour prototype delivery with free DFM analysis, which is 30% faster than competitors.

And quality excellence drives the DNA of Best Technology. ISO quality standards are rigorously implemented throughout our entire workflow, spanning material procurement, manufacturing, quality inspection, packaging, and extending to sales and marketing operations. From single sided rigid PCB design optimization to single sided rigid PCB prototype validation and single sided rigid PCB mass production, pls feel free to consult our engineers for tailored solutions.

How to choose a single sided rigid PCB manufacturer?

Choosing the right manufacturer shouldn’t be stressful. Just follow a few smart steps:

- Define your needs: Know your board size, copper thickness, surface finish, and lead time.

- Check credentials: Always ask for ISO certifications, UL files, and test reports.

- Ask about sample runs: Reliable manufacturers offer low-cost samples before mass production.

- Evaluate customer service: Do they respond fast? Do they explain options clearly?

- Read reviews or case studies: Past clients often share valuable feedback online.

- Compare prices transparently: Cheapest isn’t always best. Look for value, not just cost.

A dependable single sided rigid PCB manufacturer becomes your long-term partner. They help solve problems, reduce lead times, and improve final product quality.

In conclusion, choosing the right single sided rigid PCB manufacturer can make a big difference in product quality, lead time, and long-term reliability. From precise single-sided PCB design to efficient mass production, a trustworthy manufacturer understands every step that matters. At Best Technology, we’re more than just a single sided rigid PCB manufacturer. We’re a trusted partner for customers in over 40 countries. From initial design to fast production and global delivery, our team is here to support your projects.

With over 18 years of experience, an in-house engineering team, and strict QC processes, whether you need a single sided PCB board, want support with multilayer PCB manufacturing, or are looking for rigid-flex PCB manufacturers, Best Technology is always ready to help. Warm welcome to contact us at sales@bestpcbs.com.