As is well known, solderability is very important for any type of printed circuit boards, we must do solderability test of each batch PCB we made. In this way we can inspect the weldability of the PCB before we go ahead the assembly process, much helpful for SMT.

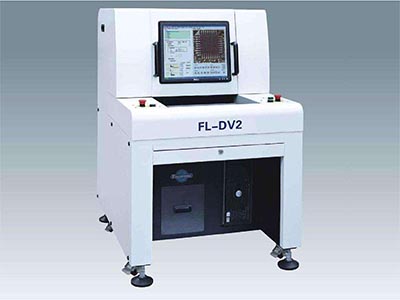

In our circuit board manufacturing workshop, we have professional equipment to do that testing. But normally these equipment was expensive, and a lot of people want to know a simple and cheap way to do that solderability testing, so today we are doing a simple solderability test and show you all the steps.

1. Take a small solder pot, plug in the power, turn on the switch and heat the solder pot to a certain high temperature(about 8 minutes).

2. Put a tin bar to the solder pot, then you can see the tin bar is begin to melting, slowly into liquid tin, then more and more.

Tin Bar

3. After few minutes, there will be enough melting liquid tin in the solder pot to do this test.

melting-tin

4.Use a tweezers to pick up a PCB circuit, first clean the PCB with rubbing alcohol. Because the unclear surface or the oxidation of the PCB will affect the test result.

5. This is the key step of this test, put the PCB into the solder pot, depth about 2 mm,time 4-5 seconds is ok. Then you can see the tin will go into the hole of the PCB.

Solderability Test 1

Solderability Test 2

6. Take out the PCB from the solder pot and put it into the cold water. After few seconds, you can see the experimental effect.

Test Results

This solderability test is very simple and easy. We can see the results very soon. We, Best Technology did solderability of every batch PCB we made, and we also supply our customers with the solderability test report and the test samples.

Any comments about that, leave your message or write email to us. Best Technology, always to be your best partner of circuit boards in China!