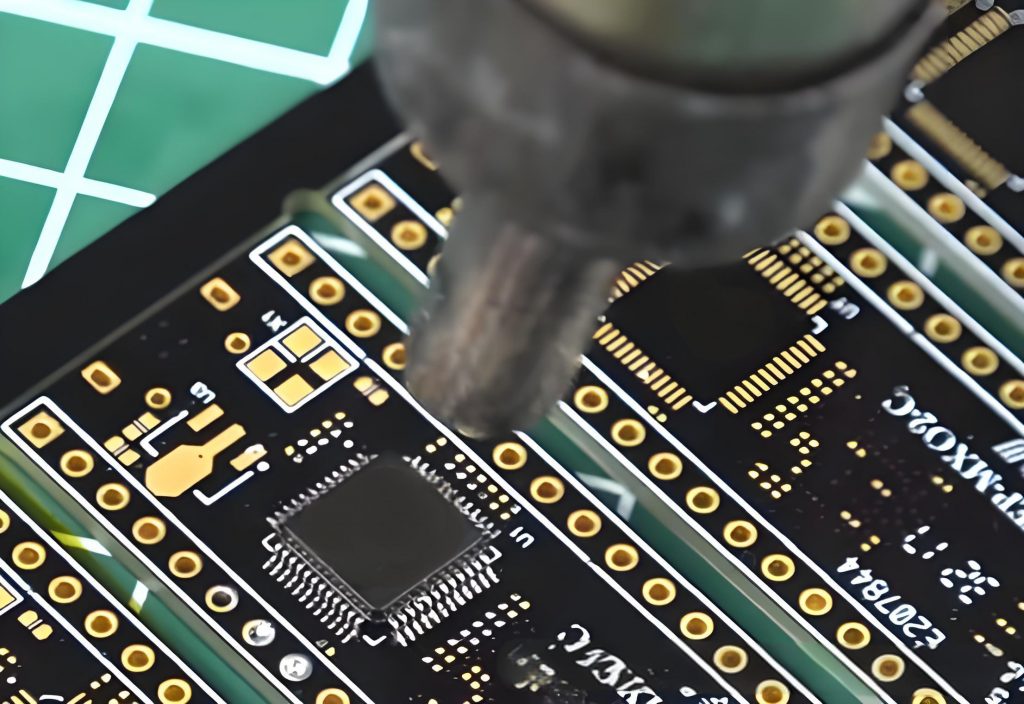

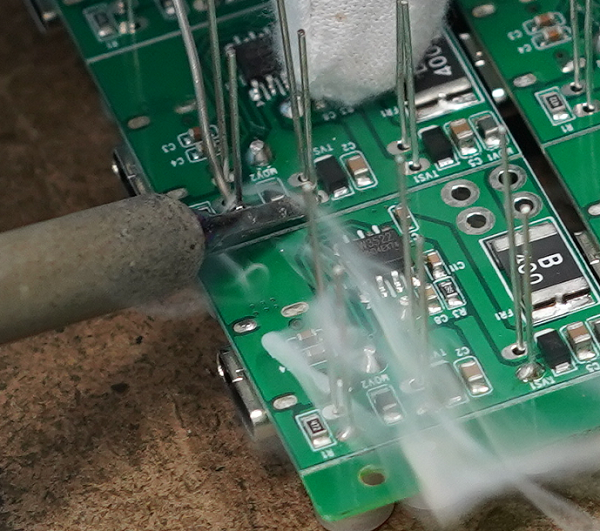

Hot bar soldering is a soldering method that uses heat and pressure to connect two or more materials together. The basic principle is to heat the surface of the material to a certain temperature to soften or melt it, and then apply a certain pressure to form a strong bond between the materials.

What is the hot bar process?

Hot bar soldering is a soldering method that applies pressure at a specific temperature. The process involves applying a pressure of 0.5 to 1.5N at a temperature above 200°C, so that the splitter brings the lead into contact with the soldering area and reaches the atomic distance, thereby generating an interatomic force to achieve the purpose of bonding.

Specifically, during hot bar soldering, the temperature is usually above 200°C and the bonding strength is between 0.05 and 0.09N.

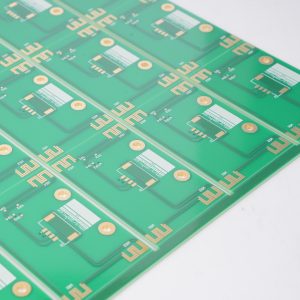

Hot bar soldering is widely used in the field of microelectronic surface assembly technology, especially in connecting flexible circuit boards and rigid circuit boards. The stability and efficiency of this process are essential to ensure the good quality of the product.

What temperature is hot bar soldering?

The temperature range of hot bar soldering is usually between 200-400°C below the melting point of the material. Because within this temperature range, the metal surface can melt and fuse together with the help of pressure, forming a high-quality weld.

Hot bar soldering is a method of joining two or more metal materials together by applying heat and pressure at the material joint, causing the material surface to melt and fuse together with the help of pressure.

Temperature is a critical parameter in the hot bar soldering process because it directly affects the quality of the weld and the structure of the metal. If the temperature is too low, the molten pool may not form, resulting in an incomplete connection; while too high a temperature may cause the material to melt excessively and damage the metal structure.

The temperature range of hot bar soldering is affected by many factors, including the properties of the metal, pressure, and welding time. The melting point of the metal is one of the most important parameters affecting the temperature selection, and welding is usually performed below the melting point of the material. Pressure and time also have a direct impact on the welding process because they have a direct impact on the contact and melting of the metal.

In practical applications, choosing the right temperature requires a comprehensive consideration of multiple factors. In the production of multilayer boards, the hot pressing temperature is generally between 150â and 180â, and the specific temperature can be adjusted according to the type of glue used and the characteristics of the board.

In addition, the operating temperature range of high-frequency heat welding machines is generally between 100â and 300â, and some special materials may require higher temperatures, up to 600â.

What is a hot bar?

Hot pressing welding is a welding method that uses heat energy and pressure to melt and fuse two or more materials together at the contact surface. It is usually carried out at a temperature above 200°C and a certain pressure is applied to make the chopper bring the lead to contact the welding area and reach the atomic distance, thereby generating interatomic forces to achieve the purpose of bonding.

Why use hot air soldering?

The main reasons for using hot air soldering include its high efficiency, energy saving, environmental protection, high strength and wide application range.

- High efficiency: hot air welding has a fast speed and can greatly improve production efficiency.

- Energy saving: Compared with traditional welding methods, hot air welding consumes less energy and can reduce energy consumption.

- Environmental protection: Hot air soldering does not require the use of additional substances such as chemical agents, does not produce harmful substances, has little pollution to the environment, and meets environmental protection requirements.

- High strength: The weld of hot air soldering is uniform and strong, and the material after welding is not easy to deform.

- Wide range of applications: Hot air soldering is suitable for various metal materials, as well as a variety of plastic materials.

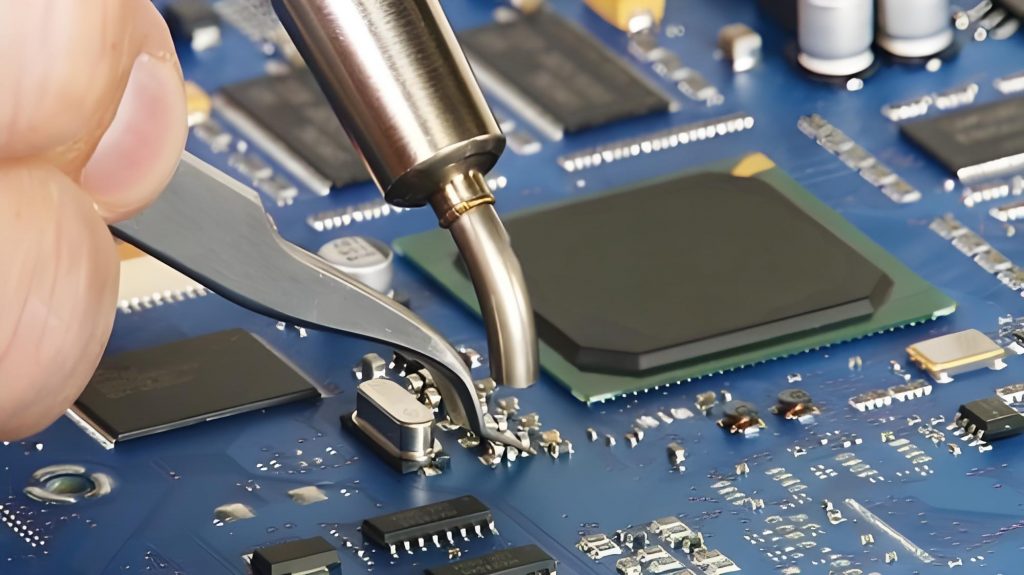

Is hot air soldering better than iron?

Hot air soldering and soldering iron each have their own advantages and disadvantages. The choice of which soldering method depends on the specific application requirements.

Advantages of hot air soldering

- High efficiency: The efficiency of hot air soldering is usually higher than that of soldering iron, which is suitable for the removal and welding of large amounts of solder.

- Temperature control: Hot air soldering can accurately control the welding process by adjusting the wind force and temperature, and is suitable for handling large-area welding tasks.

- High safety: Hot air soldering guns generally use safe voltages and have anti-static functions, reducing the risk of electric shock and static damage to components.

Advantages of soldering irons:

- Accurate temperature control: The temperature control of soldering irons is more accurate, which is suitable for occasions that require precise welding, such as the welding of microelectronic components.

- Flexible operation: The soldering iron is more flexible to operate and is suitable for delicate soldering work.

- Low cost: The initial investment and operating cost of the soldering iron are usually low, which is suitable for users with limited budgets.

Applicable scenarios:

- Hot air soldering: Suitable for removing and soldering a large amount of solder, such as circuit board repair and large-area soldering during manufacturing.

- Soldering iron: Suitable for occasions that require precise soldering, such as soldering of microelectronic components and delicate circuit board repair.

In summary, hot air soldering and soldering iron have their own advantages and disadvantages, and which method to choose depends on the specific welding needs and application scenarios.

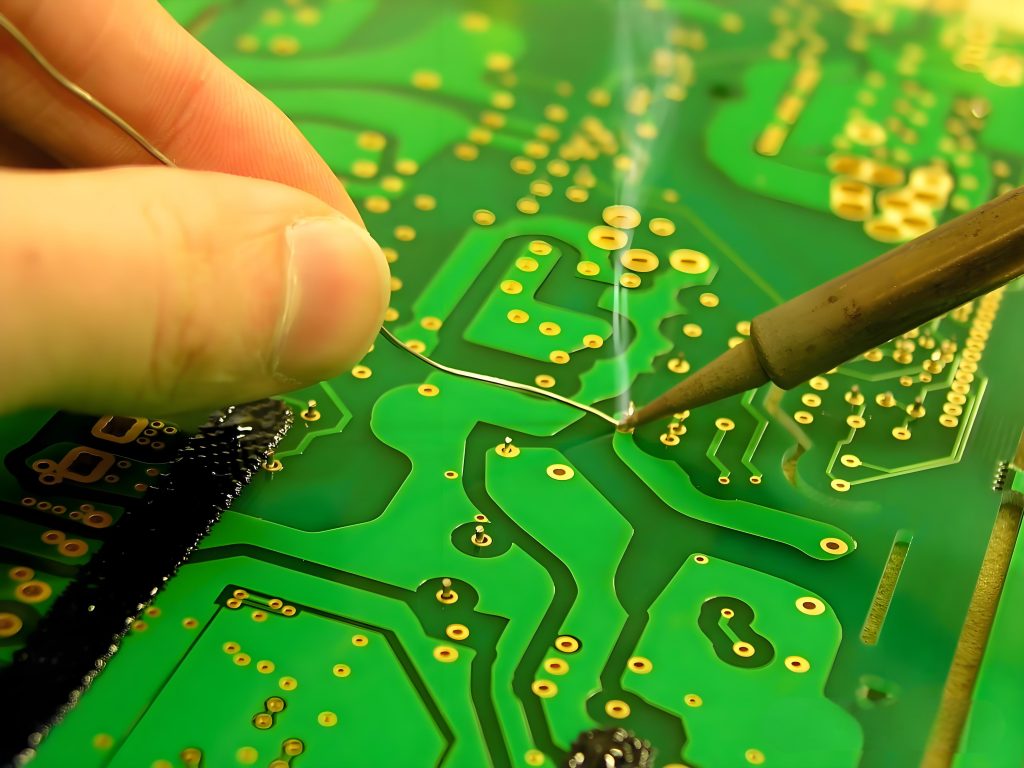

How to use bar solder?

The basic steps for using solder bar are as follows:

- Preparation stage: First, put an appropriate amount of solder bar into the tin pot, connect the power supply and turn on the power switch, and adjust the temperature to about 250â. Use the solder bar to tin the red heating tube until the tin surface covers the heating tube.

- Melting process: When the tin bar begins to melt, new solder bar should be added in time until the molten tin surface reaches a suitable height. When there is no solder in the tin melting furnace, do not use the tin melting furnace to heat it.

- Temperature control: The set temperature should not be too high to avoid accelerated oxidation of the tin surface. It is generally more appropriate to set it at around 300â, and the specific temperature can be adjusted according to the use requirements.

- Wave soldering process: During the wave soldering process, the content of the solder bar will continue to decrease. When the content is low to a certain extent, new solder bars should be added in time to maintain the height of the solder liquid and reduce the oxidation of the solder bar due to excessive tin wave drop.

- Lead solder bar: If lead solder bar is used, it is necessary to remove impure copper and regularly check the solder composition in the soldering furnace.

How does laser soldering work?

Laser welding is an advanced welding method that uses a high-energy-density laser beam as a heat source to locally heat two or more metal or non-metal materials to a molten or partially molten state, and then quickly cools and solidifies to achieve connection.

The working principle of laser welding can be divided into the following steps:

- The laser generates a high-power laser beam: The high-power laser beam generated by the laser is focused on the surface of the material to be welded through a lens or other optical elements to form a small spot.

- The spot has a strong thermal effect on the surface of the material: The spot has a strong thermal effect on the surface of the material, causing it to quickly heat up to the melting point or boiling point, forming a liquid or gaseous molten pool or vaporization hole.

- The laser beam moves along a predetermined trajectory: The laser beam moves along a predetermined trajectory, causing the molten pool or vaporization hole to extend along the direction of the weld. At the same time, due to surface tension and capillary action, adjacent materials flow into the molten pool or vaporization hole to fill the gap.

- The molten pool or vaporization hole cools and solidifies rapidly: After the laser beam is removed, the molten pool or vaporization hole cools and solidifies rapidly to form a uniform, dense, and high-strength weld.

In short, hot pressing welding, as an efficient and reliable connection technology, plays an important role in modern industrial production. With the continuous advancement of science and technology, hot pressing welding technology will continue to develop and innovate to provide better connection solutions for the development of various industries.