PCB soldering temp varies due to different soldering processes and materials. Manual soldering temperature is generally between 300℃ and 350℃; wave soldering temperature is usually between 245℃ and 265℃; reflow zone temperature of reflow soldering is generally between 210℃ and 240℃. The lead-free soldering standard is 260℃±5℃, while the lead soldering standard is 230℃±5℃.

What is the best soldering temperature for PCB?

The ideal soldering temp depends on the type of solder used. Most lead-based solders melt at around 183°C (361°F), while lead-free solders require about 217-227°C (423-441°F).

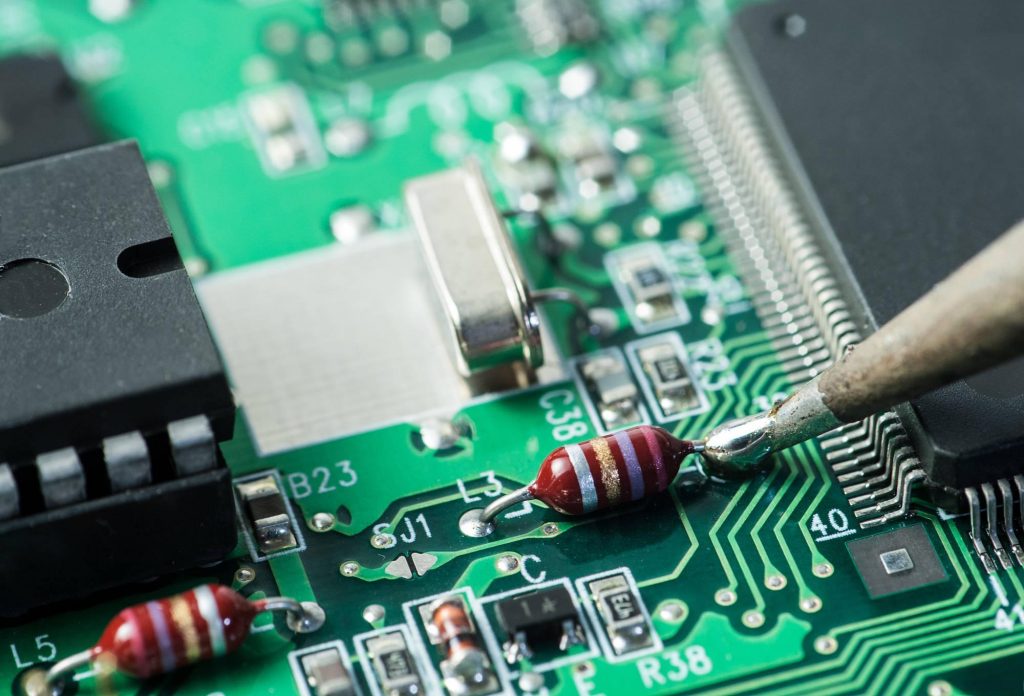

For manual soldering, a soldering iron temperature of 300-350°C (572-662°F) works well for most applications. Using a temperature-controlled soldering iron helps maintain precision.

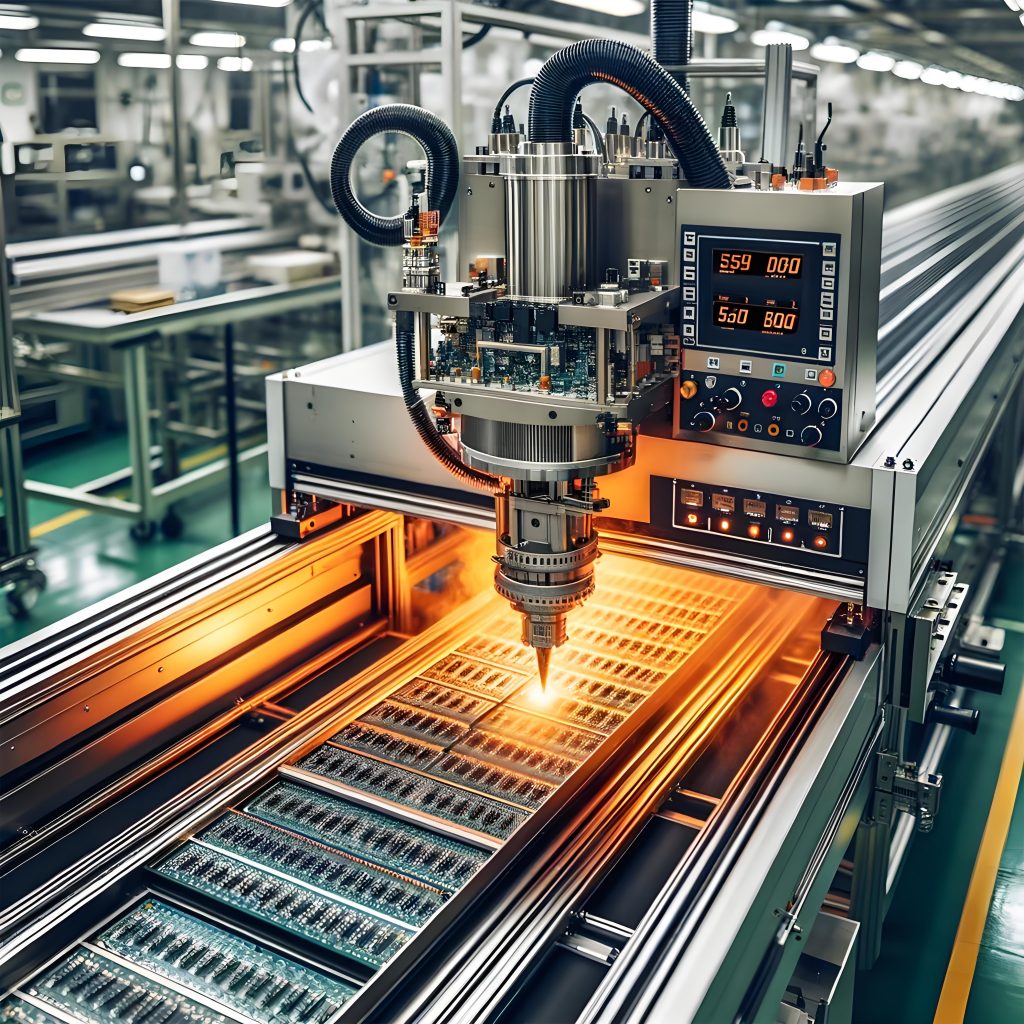

For automated soldering, such as wave or reflow soldering, temperature profiles are more complex. A gradual heating and cooling process ensures strong and reliable joints.

Do you need flux to solder PCB?

Yes, flux is essential. It removes oxidation, allowing solder to flow smoothly and bond properly. Without flux, solder may form weak or unreliable joints.

Most solder wires have flux inside, but extra flux may be needed for complex PCB assemblies. For surface-mount devices (SMDs), a no-clean or rosin flux is commonly used.

Using the right flux improves soldering efficiency and enhances the durability of the connections.

What temperature does PCB solder reflow at?

Reflow soldering is used for SMD assembly. It follows a controlled temperature profile to melt solder paste and bond components.

A typical lead-free reflow profile includes:

- Preheat: 150-200°C (302-392°F)

- Soak: 200-217°C (392-423°F)

- Reflow peak: 230-250°C (446-482°F)

- Cooling: Gradual cooling to below 180°C (356°F)

Lead-based solder requires lower peak temperatures, around 215-225°C (419-437°F).

What temperature do you solder header pins to PCB?

Header pins require a stable temperature between 320-350°C (608-662°F) for effective soldering.

Using a lower temperature can result in cold joints. Higher temperatures may damage the plastic housing or PCB pads. A controlled approach ensures strong electrical and mechanical connections.

Flux application also helps the solder flow better, improving joint quality.

What temperature is flexible PCB soldering?

Flexible PCBs (FPCs) are heat-sensitive. Excessive heat can damage the substrate. A controlled soldering temperature of 280-320°C (536-608°F) works best.

For reflow soldering, a peak temperature of 230-245°C (446-473°F) is common. Careful handling and gradual heating prevent warping or delamination.

Low-temperature solder pastes can also be used to reduce thermal stress on flex circuits.

What temperature is SMD soldering?

SMD soldering involves reflow, hot air, or manual soldering techniques. The temperature depends on the method used:

- Reflow soldering: 230-250°C (446-482°F) peak temperature.

- Hot air rework: 280-350°C (536-662°F) depending on component size.

- Manual soldering: 300-350°C (572-662°F) with a fine-tip iron.

Precise temperature control is critical to avoid thermal damage to small SMD components.

What temperature should SMT soldering be?

Surface-mount technology (SMT) soldering mainly relies on reflow soldering, where temperature must be carefully controlled.

A standard SMT soldering profile includes:

- Preheat: 150-180°C (302-356°F)

- Soak: 180-220°C (356-428°F)

- Peak: 230-250°C (446-482°F) for lead-free solder

- Cooling: Gradual cooling to prevent thermal stress

SMT soldering ensures high precision and reliability, making it the preferred method for modern PCB assembly.

What wattage for pcb soldering?

Soldering iron wattage impacts performance. For PCB work, 30-60W irons are ideal.

- 30W-40W: Suitable for fine soldering tasks.

- 50W-60W: Best for general PCB soldering, including through-hole and SMD.

- Above 60W: Needed for heavy-duty tasks, like soldering large connectors.

A temperature-controlled soldering station provides better accuracy and prevents overheating.

What is the temperature range for pcb soldering process?

The full temperature range for PCB soldering varies by method:

- Manual soldering: 300-350°C (572-662°F)

- Wave soldering: 245-265°C (473-509°F)

- Reflow soldering: 230-250°C (446-482°F)

- Hot air rework: 280-350°C (536-662°F)

Different materials and components may require adjustments. Following the right temperature range ensures better quality and durability.

Conclusion:

Soldering temp is critical for PCB assembly. The right temperature ensures strong, reliable joints while preventing component damage.Each soldering method requires specific temperature settings. Whether manual soldering, SMT, or reflow, precision control is key.

For expert PCB soldering and assembly solutions, trust Best Technology. Contact us at sales@bestpcbs.com for expert PCB solutions.