In the vast field of materials science, copper occupies an important position with its excellent performance. Among them, the thermal conductivity of copper is particularly eye-catching, becoming the preferred material for heat conduction in many fields. Copper plays an important role in electronic equipment, heat exchangers, construction and other fields.

What is the thermal conductivity value for copper?

The thermal conductivity of copper is about 401W/m·K. â

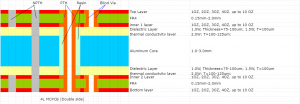

The thermal conductivity refers to the heat transferred through 1 square meter of area in 1 second under stable heat transfer conditions, with a temperature difference of 1 degree (K, â) on both sides of a 1 meter thick material. The unit is watt/meter·degree (W/(m·K)).

The thermal conductivity is a parameter to measure the thermal conductivity of a material. The larger the value, the better the thermal conductivity. Due to its high thermal conductivity, copper is often used to make radiators, heat conductors and other applications that require efficient heat transfer.

What is the thermal conductivity of copper at 25 C?

The thermal conductivity of copper is affected by many factors. On the one hand, temperature is an important influencing factor. Generally speaking, the thermal conductivity of copper decreases with increasing temperature.

At 25â, the thermal conductivity of copper is about 401W/m.K, and at 100â, the thermal conductivity of copper is 377W/mã»K.

How do you measure thermal conductivity of copper?

The thermal conductivity of copper is usually measured by the steady-state method. â

The steady-state method is a classic method for measuring the thermal conductivity of thermal insulation materials. It uses the equilibrium state in which the heat transfer rate is equal to the heat dissipation rate during stable heat transfer.

This method has a simple and clear principle and high accuracy. Although the measurement time is long and the environmental conditions are high, it is suitable for measuring thermal conductivity materials at medium temperatures, especially for low thermal conductivity materials such as rock, plastic, rubber, glass, and thermal insulation materials.

In the steady-state method, commonly used methods include heat flow method, protected heat flow method, and protected hot plate method. The basic principles of these methods are similar, but some standards are formulated for different thermal insulation materials, and the test results are similar.

What metal has the highest thermal conductivity?

Silver has the highest thermal conductivity.

Among metals, silver has a thermal conductivity of 411W/(m·K), which is the highest value among all metals. This property of silver makes it the metal with the best thermal conductivity.

In contrast, copper has a thermal conductivity of 401W/(m·K), which is also very high, but still slightly lower than silver. Other metals such as gold and aluminum have thermal conductivities of 315W/(m·K) and 237W/(m·K), respectively, which are lower than silver and copper. Therefore, from the perspective of thermal conductivity, silver is undoubtedly the metal with the best thermal conductivity.

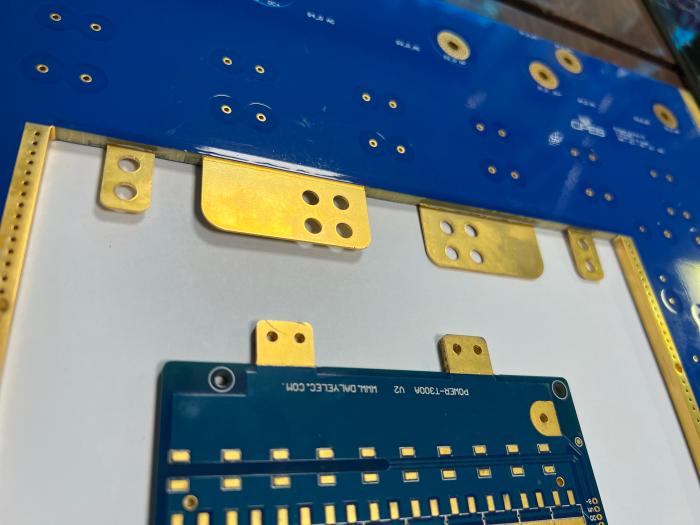

In addition, although the thermal conductivity of copper is also very high, reaching 401W/(m·K), second only to silver, among pure metals, the thermal conductivity of silver is still the highest. However, in practical applications, copper is widely used because of its good conductivity and relatively low cost.

Which metal is the poorest conductor of heat?

The metal with the worst thermal conductivity is iron. â

Among metal materials, the thermal conductivity of iron is 0.163, while that of copper and silver is, and that of aluminum is 0.5. These data indicate that the thermal conductivity of iron is significantly lower than that of other common metals. Therefore, it can be concluded that iron is the metal with the worst thermal conductivityâ.

Why copper has highest thermal conductivity?

Copper has the highest thermal conductivityâ, mainly because of its unique physical and chemical properties. The superior thermal conductivity of copper is mainly attributed to its crystal structure and electronic properties.

Copper is a metal with good electrical and thermal conductivity, which is due to the presence of a large number of free electrons in the crystals of copper. These free electrons can effectively transfer heat when colliding with metal cations in the crystal, making copper extremely thermally conductive.

The thermal conductivity of copper is about 400 W/m·K, which means that copper transfers much more heat per unit time than most other materials. The high thermal conductivity allows copper to quickly transfer heat away, with efficient heat dissipation.

What happens to copper when it is heated?

When copper is heated, its volume increases, its mass remains unchanged, and its density decreases. â

When copper is heated, its volume increases due to the property of thermal expansion and contraction. This is because when the copper block is heated, the distance between atoms increases, resulting in an increase in volume. At the same time, the mass of copper is a property of matter, which is only related to the amount of matter contained, and has nothing to do with the position, state, shape, and temperature of the object. Therefore, the mass of copper remains unchanged after heating.

In addition, when copper is heated in the air, if it reacts with oxygen, black copper oxide (CuO) will be generated on the surface. This chemical change will cause the color of copper to change from red to black.

In summary, when copper is heated, not only will its volume increase, its mass remain unchanged, and its density decrease, but it will also react with oxygen to generate copper oxide when heated in the air, resulting in a change in surface color.

Why does copper turn green?

Copper turns green because it is oxidized in the air to form copper rust. The main component of this copper rust is basic copper carbonate, which is green in color. â

Copper will be oxidized in the air to form copper rust. This rusting process is the result of a combination of factors, including the reaction of copper with oxygen, water vapor and carbon dioxide in the air.

Specifically, when copper is exposed to oxygen, water and carbon dioxide in humid air for a long time, a chemical reaction will occur to generate basic copper carbonate (Cu2(OH)2CO3), a green inorganic compound, so a green rust layer will form on the copper surface.

This process not only occurs on the surface of copper, but also because the main component of copper rust is basic copper carbonate, the color of copper rust is green, which makes the appearance of copper products appear green.

Copper has become the preferred material for heat conduction in many fields due to its high thermal conductivity, good processing performance and stable thermal conductivity. With the continuous advancement of science and technology, it is believed that copper will continue to play an important role in future development.