In the aluminum PCB design, people always mention the thermal conductivity value. Do you know what about thermal conductivity and you know what is the role of this layer in the aluminum core circuit board? Welcome to keep reading if you are interested in it.

What is thermal conductivity?

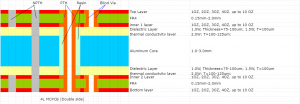

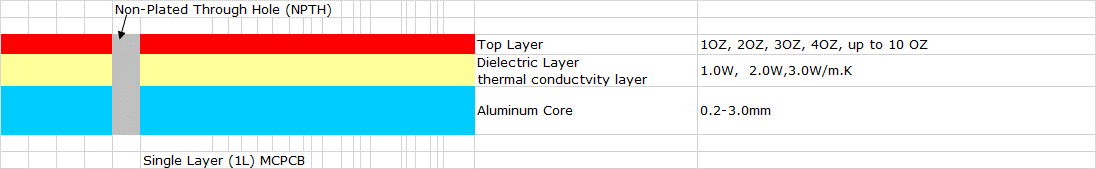

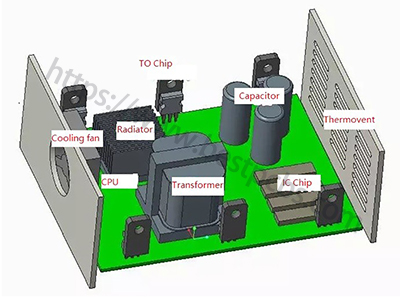

Thermal conductivity is a physical value signifies the capacity of a material to allow heat flow per unit area through it in a unit of time. A higher thermal conductivity indicates better heat conduction for the material. In the field of heat generation and thermal management products, thermal conductivity is a crucial parameter as it relates to the product’s heat dissipation capability and stability. In the structure of aluminum, the thermal conductivity layer is always stand between the copper circuit layer and base material, so that the heat generated by product can be transfer quickly to outside.

Significance of Thermal Conductivity in Aluminum PCBs

Aluminum substrates are commonly used materials in heat dissipation and thermal management products. Their thermal conductivity is a vital element evaluated heat dissipation properties typically in W/m·K. It can be understood as the material’s heat transfer rate, i.e., the amount of heat conducted per unit time. Specifically, assuming the same amount of heat is conducted in aluminum substrates and other materials, the conduction rate of aluminum substrate will be faster over a certain period. This implies that aluminum substrates can transfer heat more quickly from the heat source to the external environment, achieving efficient heat dissipation.

Impact of Thermal Conductivity on Heat Dissipation Products

The primary function of thermal management products is to dissipate heat. How does thermal conductivity specifically affect them? Let us dive into from below aspects:

1. Thermal Conductivity Value

A higher thermal conductivity leads to better heat dissipation capability, as it can achieve faster transfer of heat from the heat source to the environment. Therefore, thermal conductivity of aluminum substrates plays a crucial role in the heat dissipation products, such as the LED lights, industrial power devices, automotives. At Best Technology, the thermal conductivity we used for aluminum PCB always is range from 1.0 to 3.0W (thickness=75-200um). Different thermal conductivity value has its own thickness.

2. Product Stability

The stability of a product also depends on its thermal conductivity. According to our 17+ manufacturing experience, insufficient thermal conductivity in heat dissipation products may result in overheating during prolonged operation, potentially shortening the product’s lifespan. Let me take a simple example, assume your mobile phone is under long time playing games, then it will generate many heats, finally causing the overheating phenomenon. And this will shorten its lifecycle if you always do like that.

When it comes to thermal conductivity selection, there is a big misunderstanding is that some may believe that higher thermal conductivity in aluminum substrates is always better. However, this is not entirely accurate. While higher thermal conductivity is generally favorable, it does not mean that aluminum substrates with the highest thermal conductivity are suitable for all heat dissipation applications. In specific use cases, it is essential to choose the appropriate thermal conductivity for aluminum substrates based on actual requirements to achieve the optimal heat dissipation effect.

By the way, if you want to choose higher thermal conductivity value, ceramic PCB is a better choice, which can achieve 24W or more. It mainly depends on its ceramic substrate material, like the Al2O3 thermal conductivity value is around 24W~28W/m-K, while AlN enable to reach 150W~240W/m-K.

Conclusion

All in all, to ensure optimal heat dissipation effects and stability, it is crucial to choose the right thermal conductivity for aluminum substrates based on actual needs. The careful consideration of thermal conductivity values in aluminum PCBs is integral to the longevity and performance of heat dissipation products, emphasizing the importance of informed selection in the pursuit of effective thermal management.

Best Technology is an expert in metal core PCB manufacturing, we have strong R&D team and full-experienced employs that can provide with you the best metal core PCB solution. Welcome to contact us at sales@bestpcbs.com if you want to know more.