A turnkey EMS PCB manufacturer provides a complete solution for the assembly of printed circuit boards (PCBs). From design and prototyping to final assembly, they manage the entire process. This all-in-one service is invaluable for businesses looking for efficiency and quality. But what exactly does this process entail, and why should companies opt for a turnkey approach? This article dives into the key aspects of turnkey EMS PCB manufacturing, comparing it with other options, and exploring the benefits and challenges it brings.

What is Turnkey EMS PCB Manufacturing?

Turnkey EMS PCB manufacturing refers to a comprehensive service where the manufacturer handles everything from the initial design to the final product. âTurnkeyâ means that the service is provided as a complete package. This typically includes designing, sourcing materials, PCB assembly, testing, and delivery.

The key advantage of turnkey EMS manufacturing is that it saves time and effort for the customer. Instead of working with multiple suppliers or manufacturers, the customer can rely on one provider for the entire process. This leads to faster timelines, better communication, and often lower costs due to streamlined operations.

What is EMS vs OEM?

Itâs important to understand the difference between EMS (Electronic Manufacturing Services) and OEM (Original Equipment Manufacturer), as these terms are often used interchangeably but serve different purposes.

EMS (Electronic Manufacturing Services): A company that provides manufacturing services, including production, assembly, testing, and logistics, based on client specifications. EMS providers do not own the IP of the products they manufacture.

OEM (Original Equipment Manufacturer): A company that designs and manufactures products or components, which are then sold to another company to be branded or integrated into their products. OEMs own the intellectual property (IP) of their products.

An OEM typically designs and creates the product, and then outsources the manufacturing process to an EMS provider. While OEMs may work with EMS providers, they maintain control over the productâs design and specifications.

What Process Does Turnkey EMS PCB Manufacturing Have?

Turnkey EMS (Electronic Manufacturing Services) PCB manufacturing is a comprehensive, end-to-end solution that handles every stage of production, from design validation to final delivery. Below is the detailed process:

1. Design Review & DFM Analysis

Design Input: The client provides design files (Gerber, BOM, assembly drawings).

Design for Manufacturability (DFM): The EMS provider identifies potential production risks (e.g., pad spacing, hole sizing) and suggests optimizations to prevent costly revisions.

Prototyping (Optional): Functional prototypes are built for validation if the design isnât finalized.

2. PCB Fabrication

Raw Board Production: Manufactures blank PCBs through processes like lamination, drilling, copper plating, etching, and solder mask application.

Quality Checks: Copper thickness verification; Impedance control (for high-frequency boards); Surface finish application (ENIG, OSP, HASL, etc.)

3. Component Sourcing & Supply Chain Management

BOM Breakdown: Segregates client-approved vendor lists (AVL) from EMS-procured components.

Risk Mitigation: Alternate component qualification (to avoid obsolescence); MOQ (Minimum Order Quantity) negotiation; Long-lead-time material stocking

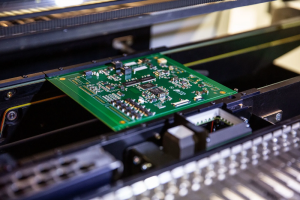

4. PCB Assembly (PCBA)

SMT Assembly: Automated placement of surface-mount components (ICs, resistors, capacitors) using pick-and-place machines.

Critical steps: Solder paste printing, reflow oven profiling

Inspection: SPI (Solder Paste Inspection) and AOI (Automated Optical Inspection)

THT Assembly: Through-hole component insertion (connectors, large capacitors) using wave soldering or hand soldering.

Post-Assembly: Cleaning (flux residue removal) or conformal coating for high-reliability applications.

5. Testing & Validation

Electrical Testing: ICT (In-Circuit Test): Checks shorts, opens, and component values. FCT (Functional Test): Validates board performance under real-world conditions.

Environmental Stress Testing (as required): Thermal cycling; Vibration testing; Burn-in testing;

Compliance: Supports certifications like CE, FCC, or UL.

6. Packaging & Delivery

ESD-Safe Packaging: Anti-static bags, foam inserts, or moisture-resistant materials.

Traceability: Labels/QR codes for batch/date tracking.

Logistics: Supports JIT (Just-in-Time) delivery, drop shipping, or warehouse management.

How to Choose a PCB Manufacturer?

Choosing the right turnkey EMS PCB manufacturer is a critical decision for any business. Here are a few things to consider when selecting a manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record in the industry. A provider with years of experience and a good reputation will likely provide high-quality results.

Capabilities and Services: Ensure the manufacturer offers the full range of services you need. Check whether they provide design assistance, component sourcing, assembly, and testing, as these can save you time and money.

Quality Control Standards: A good PCB manufacturer will adhere to international quality standards. Check their certifications and quality control processes to ensure they meet industry benchmarks.

Customer Support: Good communication is key to any successful partnership. Look for a manufacturer who provides excellent customer support and is responsive to your needs.

What Benefits Can the Turnkey EMS PCB Manufacturer Bring?

The turnkey EMS PCB manufacturer offers numerous benefits that can positively impact your business:

Simplified Process: Working with a single provider reduces the complexity of coordinating between different suppliers and manufacturers.

Cost Efficiency: By consolidating services, turnkey solutions can often be more cost-effective than hiring multiple suppliers or managing different stages of production.

Faster Time-to-Market: Turnkey manufacturers can reduce lead times by streamlining the design, assembly, and testing processes. This leads to quicker product launches.

Higher Quality Assurance: Since the manufacturer handles all aspects of the production, they are in a better position to ensure consistency and quality throughout the process.

These benefits make turnkey EMS PCB manufacturing an appealing option for companies aiming for streamlined operations and reliable results.

What Are the Key Challenges of Working with a Turnkey EMS PCB Manufacturer?

âThe key challenges of working with a turnkey EMS (Electronic Manufacturing Services) PCB manufacturer, from a positive perspective, include ensuring effective communication, managing expectations, and maintaining quality control.â

âEnsuring Effective Communicationâ: Collaboration with a turnkey EMS PCB manufacturer often involves detailed technical specifications and ongoing adjustments. Ensuring clear and timely communication is crucial to avoid misunderstandings that could lead to delays or product defects.

âManaging Expectationsâ: Both parties need to have realistic expectations about timelines, costs, and the scope of work. Managing these expectations effectively can prevent scope creep and ensure that the project stays on track.

âMaintaining Quality Controlâ: Maintaining high standards of quality control is essential when outsourcing PCB manufacturing. This involves setting clear quality benchmarks, conducting regular audits, and having a robust system in place to address any quality issues promptly.

By addressing these challenges proactively, companies can leverage the benefits of working with a turnkey EMS PCB manufacturer, such as cost savings, access to advanced manufacturing capabilities, and faster time-to-marketâ.

How to Ensure Quality Control with a Turnkey EMS PCB Manufacturer?

Quality control is crucial in PCB manufacturing, and a good turnkey EMS PCB manufacturer should have stringent quality control measures in place. Hereâs how to ensure quality:

Clear Specifications: Provide the manufacturer with detailed design and performance specifications. This helps minimize mistakes and ensures that the product meets your exact needs.

Regular Testing: Ensure the manufacturer conducts regular testing throughout the process, including before, during, and after assembly. This should include electrical testing and reliability tests.

Third-Party Audits: Consider having third-party audits or inspections done to verify the quality and compliance of the final product. This adds an extra layer of confidence in the manufacturerâs processes.

By ensuring a strong quality control process, you can reduce the risk of defects and ensure that your PCBs meet industry standards.

At Best Technology, we are committed to delivering top-tier turnkey EMS PCB manufacturing services. Our comprehensive approach combines expert design, precise component sourcing, and meticulous testing to ensure your PCBs meet the highest standards. With a focus on quality, efficiency, and customer satisfaction, we take pride in being a trusted partner for companies looking for seamless, reliable PCB solutions.

To put it in a nutshell, a turnkey EMS PCB manufacturer offers significant advantages for businesses looking to streamline their PCB manufacturing process. From design and assembly to testing and delivery, they manage it all, saving you time and effort. While there are some challenges, such as Complexity in Communication, Quality Control, the benefits often outweigh the drawbacks. By carefully selecting a reputable provider and ensuring effective communication, you can enjoy a seamless manufacturing experience with high-quality results.

If youâre looking for a reliable and efficient PCB manufacturing partner, a turnkey EMS solution might just be what you need. Best Technology is a leading turnkey EMS PCB manufacturer with years of experience in providing high-quality, reliable PCB solutions. Our expertise in the industry ensures that our clients receive the best possible solutions tailored to their specific needs, all while maintaining the highest standards of quality and efficiency. Pls feel free to contact us at sales@bestpcbs.com to get more information and personalized solutions.