What is an inverter circuit board?

An inverter circuit board is designed to manage the conversion process by controlling the flow of current, regulating voltage, and ensuring efficient energy transfer. It can control and regulate the conversion of direct current (DC) into alternating current (AC). In the application of renewable energy systems such as solar power generation and wind power generation, inverters play a crucial role. It efficiently converts the DC energy collected by solar panels or wind turbines into AC power supplies suitable for home and business use.

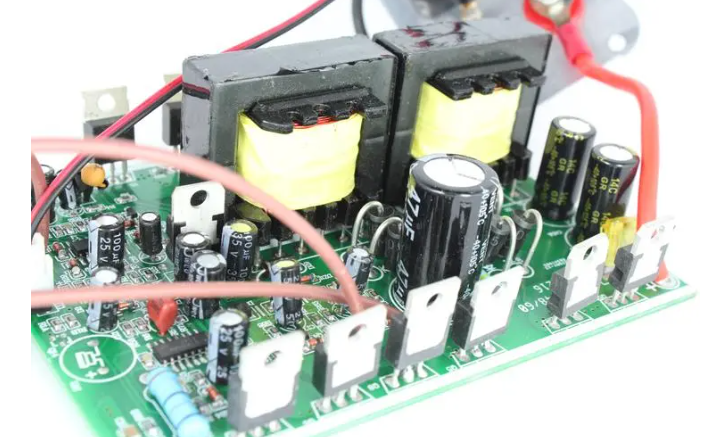

An inverter PCB typically includes components such as power semiconductors (IGBTs or MOSFETs), microcontrollers, and various passive elements that enable the inverter to function correctly.

Types of Inverter PCB

Inverter PCBs come from several types, mainly are single-sided PCB, double-sided PCB and multilayer PCB.

Single-Sided PCB

A single-sided PCB is the most basic type, with all the components and circuits mounted on one side. It is commonly used in low-cost inverters with relatively simple circuits. Due to the limited space and circuit paths, its performance and power handling capabilities are moderate. Therefore, it is suitable for small-scale inverter systems or low-power home appliances.

Double-Sided PCB

Double-sided PCBs feature components and copper circuitry on both sides of the board. Furthermore, plated through holes can be drilled on such board to improve the electricity. These PCBs are suitable for mid-range inverter designs that require a higher number of components and connections, as they provide better performance and power efficiency. In higher power applications like motor control systems and renewable energy inverters, double sided PCB are commonly used.

Multilayer PCB

Inverters designed for industrial applications or high-performance devices often require multilayer PCBs. These boards consist of three or more layers of circuitry sandwiched between layers of insulation. Multilayer PCBs can reduce electromagnetic interference (EMI) and improve signal integrity, they are excellent in complex inverter systems used in electric vehicles (EVs), large solar arrays, and industrial motor drives.

What Benefits Does an Inverter PCB Offer?

First of all, high reliability is an important advantage of inverter PCB. Through precise circuit design and high-quality assembly processes, inverter PCBs can significantly improve the stability and reliability of equipment. In addition, the modular design makes troubleshooting and maintenance more convenient.

Secondly, environmental protection is also an important feature of the inverter PCB. Conventional inverter PCBs may use halogen-containing chemical materials in the manufacturing process, which can pose potential threats to the environment and human health. The halogen-free inverter PCB adopts halogen-free substrate and lead-free welding technology, does not produce harmful environmental pollutants, and has less impact on the environment and human health.

In addition, easy to upgrade and maintain is another important advantage of inverter PCBs. When the inverter needs to be upgraded or repaired, it can be achieved by replacing or repairing specific PCB modules, without large-scale changes to the entire system, which greatly reduces the complexity and cost of upgrading and maintenance.

Finally, highly integrated is also a significant advantage of inverter PCBs. Through a highly integrated design, the size and weight of the inverter are reduced for easy installation and maintenance.

What is an Inverter Circuit Diagram?

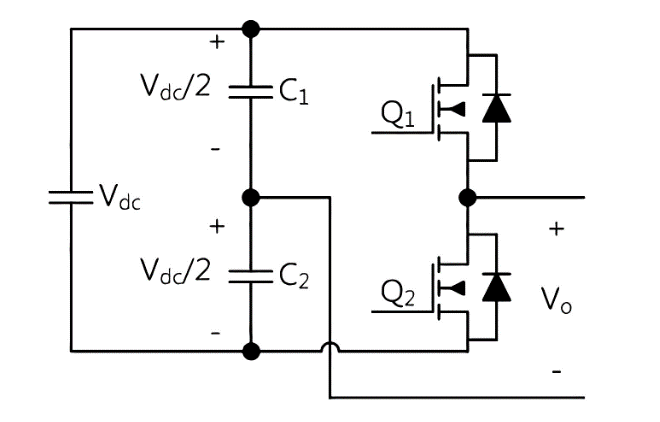

An inverter circuit diagram is a schematic representation that illustrates how the components on the PCB are interconnected to convert DC power into AC power. It provides a detailed view of the flow of current and the role each component plays within the inverter system.

The diagram typically includes:

- Power Input: Showing where the DC power is supplied, often from batteries, solar panels, or other DC sources.

- Switching Devices: Components like Insulated Gate Bipolar Transistors (IGBTs) or Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs), which are used to alternate the direction of current, producing AC power.

- Control Circuit: A microcontroller or other control logic that regulates the switching timing and frequency to generate a stable AC output.

- Filters: Inductors and capacitors used to smooth out the AC waveform and minimize harmonic distortion.

- Protection Circuits: Components that safeguard against overcurrent, overvoltage, and short circuits, ensuring safe operation of the inverter.

Applications of Inverter PCBs

Inverter PCBs are found in various applications, including renewable energy systems like solar inverters, uninterruptible power supplies (UPS), electric vehicle systems, motor drive systems, and home appliances like air conditioners, refrigerators, and washing machines. Below are the typical applications of inverter PCBs:

Solar Inverters

In solar power systems, inverter PCBs are critical for converting the DC electricity generated by solar panels into usable AC electricity for homes and businesses. Solar inverters also use MPPT (Maximum Power Point Tracking) algorithms to optimize energy harvesting.

Uninterruptible Power Supplies (UPS)

In UPS systems, inverter PCBs ensure the reliable conversion of DC battery power into AC electricity during power outages. These systems are vital in data centers, hospitals, and other environments where uninterrupted power is essential.

Electric Vehicles (EVs)

EVs rely on inverter PCBs to convert the DC power stored in the battery into AC power to drive the motor. The performance and efficiency of the inverter PCB directly affect the vehicle’s range and driving experience.

Industrial Motor Drives

Many industrial applications use AC motors for machinery and equipment. Inverter PCBs regulate the speed and torque of these motors by converting DC power into controlled AC output, they are important for automation, robotics, and manufacturing processes.

Home Appliances

Many modern home appliances, such as air conditioners, refrigerators, and washing machines, use inverter technology for energy efficiency. Inverter PCBs in these devices help control motor speed and reduce energy consumption, contributing to more eco-friendly and cost-effective home systems.

What Causes an Inverter Board to Fail?

There are many factors that can cause inverter board to fail, and some of them we can recognize by visual, but sometimes we cannot. Here we listing some potential factors that make inverter PCB be damaged or fail.

- Overheating

Excessive heat is a common cause of inverter PCB failure, particularly in high-power applications. Poor thermal management or inadequate cooling can cause components to overheat and degrade over time. For such conditions, aluminum PCBs has good thermal conductivity, this can help to heat dissipation and transfer heat out efficiently, but if the cooling system is not properly designed, even these boards can fail.

- Poor insulation

This may be due to poor installation, improper location selection and poor quality of equipment of PCB board. We can check whether the DC connector has short-circuit supports or burns due to water immersion, and whether the edges of the component become blackened.

- Low bus voltage

If this problem occurs in the morning and evening, then it is normal as the inverter tries to limit the generation conditions. If it occurs during normal daytime hours, it can be detected by above method.

- Abnormal current leakage

These problems are often caused by poor installation quality, improper location selection and poor equipment quality. We can locate the fault area and make it insulated. If the failure is caused by the material, then replace the incorrect one.

- No response

Ensure that the DC input is correctly connected and the inverter has built-in reverse short circuit protection. After the connection is restored, the inverter can start. If the inverter still does not work, it may be the fault of the inverter oscillation circuit or inverter itself has a problem. Try to troubleshooting and repair with new one.

Considerations When Choosing the Right Inverter PCB

Several factors should be considered when choose an inverter PCB for your device. Let’s talk about them.

1. Power Rating

Select a PCB that can handle the power levels required by the application. Overloading a PCB beyond its rated capacity can lead to overheating, component failure, or even dangerous situations like fire.

2. Thermal Management

In applications where heat generation is a concern, selecting a PCB with good heat dissipation is vital. Aluminum PCB or high-quality multilayer PCBs can help dissipate heat effectively. Consider heat sinks, design thermal vias, and adequate ventilation in your design to improve thermal performance.

3. Component Quality

From above, we know high quality components used in the PCB is important as well. High-quality capacitors, transistors, and diodes ensure reliable operation, even in harsh conditions. Always choose components rated for the expected load and environment, or get touch with Best Technology to enjoy a one-stop service from components sourcing and PCB assembly.

4. Environmental Resistance

If the inverter will be used in outdoor or industrial environments, choose a PCB with protective coatings, such as conformal coatings, to shield against moisture, dust, and corrosive elements. Solar power systems or outdoor motor control applications must take it in mind.

5. PCB Layout and Size

The physical size and layout of the PCB should align with the space available in the inverter system. A well-organized PCB layout helps reduce electromagnetic interference (EMI) and improves overall efficiency.

Above are all the information about inverter PCB that we can shared. If you have a question concerning the topics, please contact us.