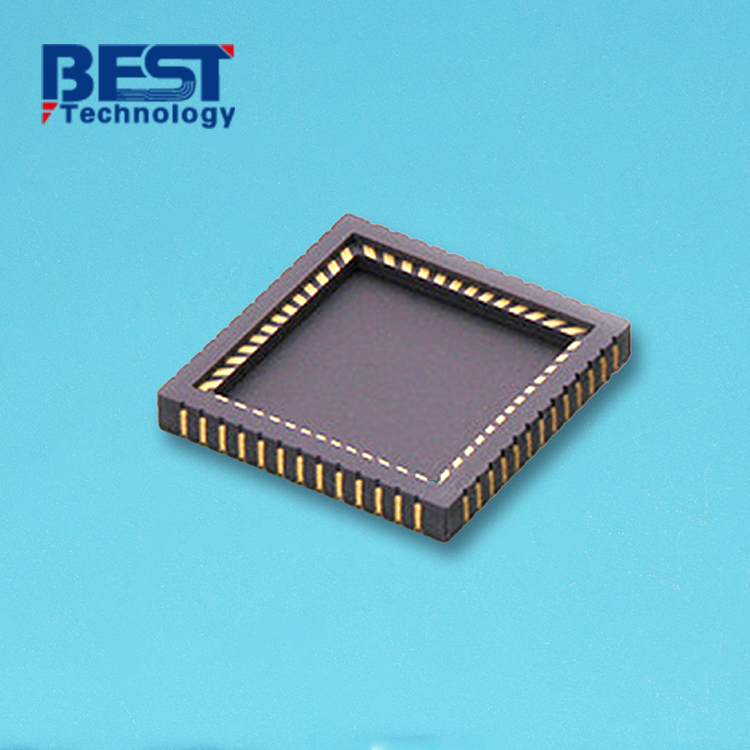

What is HTCC Ceramic PCB?

HTCC (High-Temperature Co-fired Ceramic) PCBs are manufactured using a ceramic substrate, unlike traditional fiberglass. This involves printing a heat-resistant paste made from metals like tungsten, molybdenum, and manganese onto a ceramic green billet composed of 92-96% alumina. A sintering agent of 4-8% is added, and the billet is laminated to form a multilayer structure.

This substrate is then co-fired at extreme temperatures ranging from 1500°C to 1700°C, resulting in a highly durable PCB capable of enduring harsh environments. Conductive and resistive materials are printed onto the substrate using a specialized thick-film process, creating a stable and reliable PCB that performs under demanding conditions.

Conductor Materials for HTCC Ceramic PCB

Common conductors for ceramic PCBs include metals such as gold, silver, and copper. However, HTCC ceramic PCBs, due to their high manufacturing temperature, cannot use these metals. They have low conductivity, which could result in signal delays, making them unsuitable for high-speed or high-frequency micro-assembly circuit substrates.

The primary substrates used in HTCC ceramics are aluminum oxide (Al2O3), mullite (a compound of Al2O3 and SiO2), and aluminum nitride (ALN). The sintering temperatures for these materials vary:

l Aluminum oxide (Al2O3): Sintering temperature exceeds 1550°C, with variations depending on particle size and additives.

l Aluminum nitride (ALN): Due to its small self-diffusion coefficient, sintering requires a temperature of over 1800°C, along with sintering additives to promote densification.

With so high sintering temperature, then the conductor material for HTCC ceramic PCB needs to meet these two key points:

1. The conductor metal can withstand high temperature, so from the melting point, the general requirement is not less than 1700C.

2. 2.The metal material will not react with Al2O3 and ALN at high temperature.

So in conclusion, the tungsten, molybdenum, nickel, manganese and platinum are suitable for high temperature co-firing (HTCC) ceramic circuit board.

Ceramic Substrate Selection for HTCC

The three most common HTCC ceramic substrates are Al2O3 ceramics, ALN ceramics, and Mullite ceramics. The choice of material affects the application of the HTCC ceramic PCB, with each material having its pros and cons.

Al2O3 (Aluminum Oxide)

This material densifies during sintering, shrinking the sample by 15-20%. The most commonly used variant is 99.99% Al2O3 HTCC ceramics, which have low manufacturing costs, high thermal conductivity, and excellent bending strength. However, Al2O3 HTCC ceramics have drawbacks, including:

1. High dielectric constant, limiting signal transmission speed.

2. High conductor resistivity, causing significant signal loss.

3. Incompatibility with silicon due to differing thermal expansion coefficients, restricting its use in supercomputers.

Features of Al2O3 substrate

|

Item |

Value |

|

Dielectric constant |

9.5-9.9 |

|

Density (g/cm3) |

3.8-3.95 |

|

E-Modules (Gpa) |

340-380 |

|

Poisson |

0.2-0.23 |

|

Bending strength (Mpa) |

450-650 |

|

Thermal conductivity (W/m.k) |

25-35 |

|

Thermal expansivity (ppmC-1) |

6-8 |

|

Moh’s hardness |

9 |

|

Dielectric loss (25C, 1MHz) |

0.0001 |

|

Volume resistivity (Ohm.cm) |

1x1014 |

|

Dielectric breakdown voltage (KV/mm) |

>15 |

|

Sinter temperature |

1500-1700 |

ALN (Aluminum Nitride)

ALN has better dielectric properties than Al2O3, with high thermal conductivity and a thermal expansion coefficient that matches well with semiconductor materials like Si, SiC, and GaAs.

|

Substrate |

Melting point (Degree) |

Thermal conductivity (W/m.k) |

Relative dielectric constant |

Dielectric breakdown voltage (KV/mm) |

|

Al2O3 |

1860 |

29 |

9.7 |

10 |

|

AlN |

2470 |

240 |

8.9 |

15 |

ALN also excels in harsh environments, making it suitable for applications such as sensor packaging and LED packaging. However, ALN faces challenges such as:

1. High resistivity of the wiring conductor, leading to signal loss.

2. High energy consumption due to its high sintering temperature.

3. Diminished thermal conductivity when co-fired with metals like tungsten and molybdenum.

4. Incompatibility with screen-printed resistors and passive components during high-temperature co-firing.

5. The outer conductor requires nickel-gold plating for oxidation protection and enhanced conductivity.

Despite these limitations, ALN remains a strong contender for high-reliability and high-temperature applications, such as optical communication and MEMS packaging.

Why HTCC Requires Air or Reduction Atmosphere for Sintering?

The conductor materials used in HTCC ceramic PCBs, mainly base metals, are prone to oxidation at high temperatures. For instance:

l Tungsten oxidizes rapidly above 350°C.

l Molybdenum oxidizes at 520°C, forming molybdenum trioxide, and oxidizes even faster above 600°C.

l Nickel begins to oxidize at 400°C.

l Manganese oxidizes to manganese dioxide (MnO2) at elevated temperatures.

To prevent oxidation during the co-sintering process, a reducing atmosphere—typically hydrogen—is used.

Platinum, a precious metal, can be co-sintered directly with ceramics in an air atmosphere due to its stable chemical properties. It does not oxidize and offers unique catalytic properties, making it useful in specialized applications.

How to Ensure High-Quality HTCC Ceramic PCBs?

When seeking high-quality HTCC ceramic PCBs, it is essential to partner with a manufacturer with a proven track record in this specialized field. The manufacturer should offer detailed insights into their production process and quality control measures, ensuring your specific requirements are met. Best Technology, certified by ISO9001, ISO13485, and IATF16949, adheres to strict quality control systems throughout manufacturing, making them a reliable partner for your HTCC ceramic board needs in China.