We offer consignment, full turnkey and partial turnkey assembly services.

We source all the parts directly from the manufacturers or from authorized distributors such as Digikey, Mouser,Future,TTI,Avnet and Arrow to avoid counterfeit parts.

We also warehouse a significant inventory of common parts.If we cannot source a specific component, our engineers will make recommendations for fair-price alternatives.

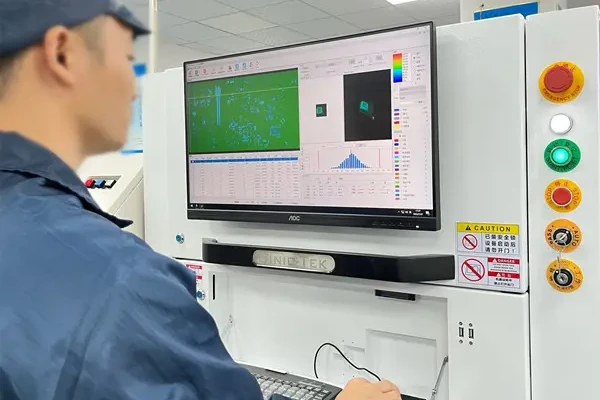

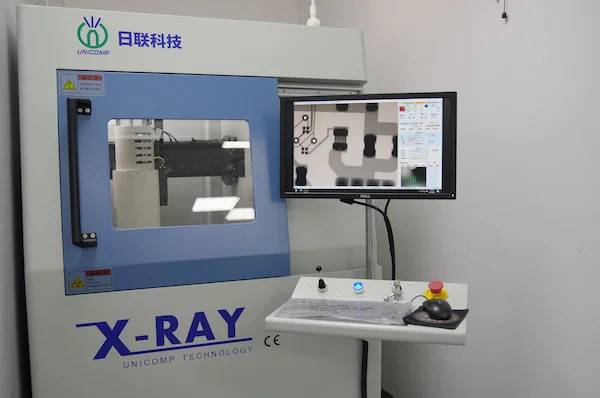

Get a free consultationWe ensure high quality and fast delivery of the PCBA assembly. Our facility equipped with advanced assembly machine and inspection equipment.

Check whether the raw materials, such as electronic components, are the same with the BOM list provided by customer, ensure the raw materials meet the customer’s requirement.

Mounting of surface-mount components and through-hole components are completed after this stage.

We strictly follow the IPC standards and customer standards to inspect and control the delivery quality.

Using state-of-the-art equipment to give you faster assembly times, higher levels of accuracy, and lower costs

Best Technology is a well-known PCB manufacturer and PCB assembly for over 18 years. We offer full turnkey PCB design and PCB layout service. All you have to do is provide the idea, and we'll make it come true.

Our products ranging from standard FR4 PCB, multi-layer PCBs, metal-based PCBs (MCPCBs), ceramic PCBs, flexible and rigid-flexible PCBs to high frequency PCBs. Currently our mouthy capability is 260,000 square feet (28,900 square meter), more than 1,000 different boards will be completed. We also provide expediate service, so that urgent boards can be shipped out within 24 hours.

At a custom printed circuit board manufacturer, we believe that continuous growth is the key to success. So, we always invest much in research and development to stay ahead of industry trends. Our focus on product quality and customers satisfaction, and we aim to build strong relationships and offer personalized support and solutions to our customers.

18 years-experience in PCB manufacturing and PCB assembly, we have reasonable factory price and short lead time to make sure your schedule smoothly.

We are committed to offering high-quality PCB solutions at competitive prices. By optimizing our production processes and managing costs efficiently, we ensure that you get the best value for your investment.

At Best Technology, quality is our top priority. We perform strict quality control procedures cover every stage of production, from raw material selection, prototyping to final product testing.

Our all-in-one approach simplifies supply chain, shorten lead times, and improves communication efficiency. And we have one-on-one sales-assistant service to give you a wonderful experience work with us.

We understand the importance of meeting your project deadlines, and we offer online WIP updates to make sure you can keep track of the progress of your PCB product.

As we all know if ceramic PCB is very fragile, so it is not easy to do SMT for them. But Best Technology can do the SMT for ceramic PCB very easily. Because we do it every day and we have more than 18 years experiences for doing that.

For the almost SMD components (such as SMD resistors, capacitors, diode etc.), normally we will add the solder paste by using SMT stencil, then put the components by machine, finally do the oven reflow.

For some special components, we will need to solder it by hand, such as through connectors, but it can’t be soldered by hand directly, it needs to be put on the heating table to keep the temperature is high enough to make the solder past at melt state. Because the ceramic material with very good heat dissipation, the solder paste will be solidification very easily if do not put the ceramic PCB on heating table

For some small LED, it can’t be put by SMT machine, because no such small feeder to pick it up, then need to put it on board by hand. We can do very well for the small BGA components too.

If you would like to know more about ceramic and ceramic PCB SMT, please feel free to email me

Due to the better outcome and higher efficiency, SMT has become the primary approach used in the process of PCB assembly. In some extent, the turn-key service is a way to reduce the cost. Here are the main SMT processes during the PCB assembly.

1. Solder paste printing

2. Part mounting

3. Furnace curing

4. Reflow welding

5. AOI optical detection

6. Defective product repair

7. De-panellization

8. Grinding PCBA edge

9. Cleaning

Turnkey service reduces customers’ time in contacting with multiple suppliers for separate steps in PCB assembly manufacturing. And the scientific order arrangement system allows customers to get PCB assembly products with higher quality and less cost in a shorter time than the traditional way of PCB assembly.

SMT, whose full name is Surface Mounted Technology, is the most popular technology in electronic assembly industry. It refers to process on PCB (Printed Circuit Board), putting various electronic components on PCB, such as resistors, capacitors, inductors, and so forth. Also, there are some dos and don’ts in the whole process of PCBA.

As noted previously, there are all sorts of electronic components that will be used in the assembly process of Printed Circuit Board. Therefore, it is extremely important to take some measures to keep a check on static. Here are three steps before entering the SMT workshop.

1.Wear on anti-static clothes and hats.

2.Put your hands on static elimination instrument, one hand is okay as well.

3.Through across the air shower door.

Only finishing the three steps above can we enter the PCB assembly workshop. And after entering the workshop, there are also something needed to be prepared.

And Best Technology is an experienced electronic company. It not only can provide PCBA service, but can provide other services, such as FPC, FR4 PCB, Rigid-flex PCB and so on. And if you have any questions about SMT, or any other questions about assembly, you are welcome to contact us.

Our team will reach out to you as soon as we can to discuss how our services can meet your needs.