What a SinkPAD Board is?

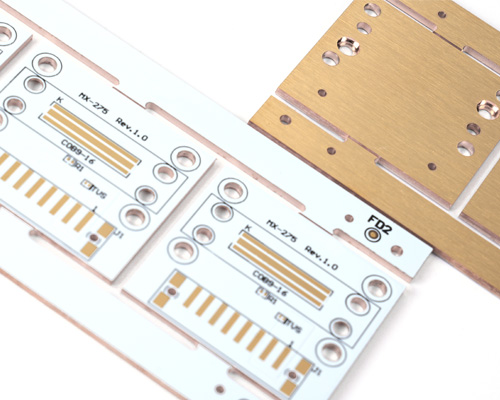

A SinkPAD Board (SinkPAD PCB) is a special type of metal core PCB, the thermal conductive PAD is convexity area of copper core/pedestal, so that the thermal PAD of LED can touch the convexity area of metal core directly, and then the heat of LED will be dissipated into the air much faster and more efficient than conventional MCPCB, so that you can get superior thermal performance for medium to high power LEDs, or even for other chips/components.

Copper is the most popular raw material used for SinkPAD metal core, as the thermal conductivity is 400W/m.K, so normally people also named it as “SinkPAD copper core board”, or “SinkPAD copper core PCB”. While the thermal conductivity of traditional Metal Core PCB is only 1-5W/m.K, as the value is limited to dielectronic layer between copper trace and metal core.

The SinkPad provides excellent heat transfer from the LED to the metal base plate/pedestal, while maintaining excellent electrical isolation. The base copper base gives the board substrate mechanical integrity, and distributes and transfers the heat to a heat sink, mounting surface or directly to the ambient air.

As the electronic trace layer was in sink area of copper core, so we named that type of board as “SinkPAD Board (SinkPAD PCB)”, and because in most of cases, the material of core is copper, so it also named as “SinkPAD copper core PCB”, or “SinkPAD copper board”.

Because the heating of LED is conducting directly into copper core, which is different from traditional thermal path, so it also named as DTP (Direct Thermal Path) MCPCB, “DTP board”, or “DTP PCB”.

The electronic related function was on trace layer and thermal conduction was on copper core, and they are separated from each other, so that layer also named as Thermoelectric separation circuit board.

SinkPAD Board (SinkPAD PCB) Classification

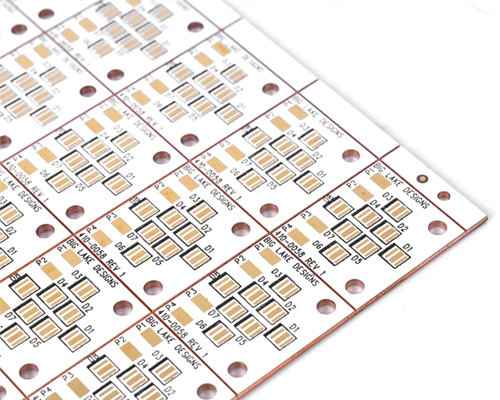

According to how many trace layers and how many sides, we are dividing the SinkPAD board (SinkPAD PCB) into these basic types:

-

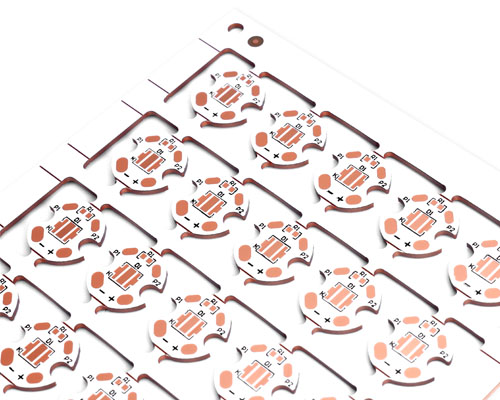

A.1 Layer SinkPAD copper core PCB: One trace layer + one side copper core. See more details about 1L SinkPAD board

-

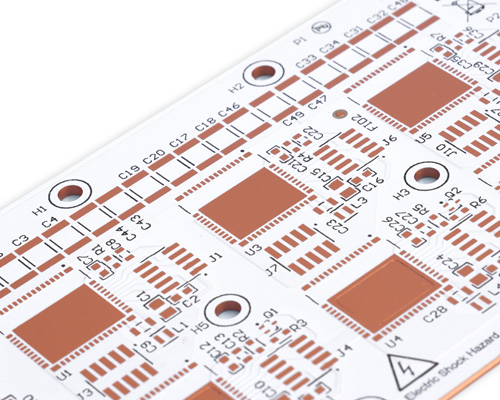

B.2 Layers SinkPAD copper core PCB: Two layers on trace layers + one side copper core. Click here to see more details on 2L SinkPAD PCB.

-

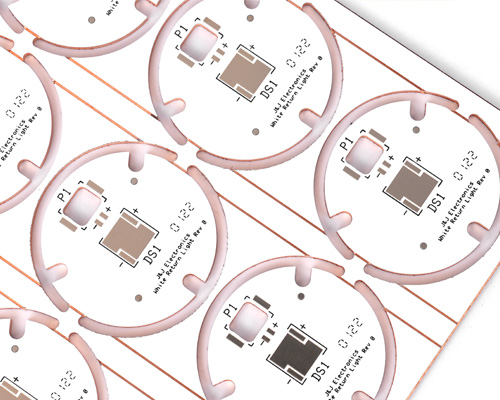

C.Double sided SinkPAD copper core PCB: There’re SinkPAD on both top and bottom side, and only one trace layer on each side. Click here to see more details on double sided SinkPAD board.

SinkPAD Board (SinkPAD PCB) Application

- The metal core is Copper with high density, strong thermal carrying capacity and higher thermal conductivity. So the volume can be smaller under the same power.

- It adopts the thermoelectric separation structure, the Lumens depreciation of the LED is minimized, and the life of the lamp is prolonged.

- Suitable for matching single high-power lamp, such as Cree XPL, XML, XHP; Osram LED, etc., also COB package LED

- High power semiconductors (transistors, thyristors, diodes) as well as resistors.

- A variety of Surface Finishing are available according to different demands. (ENIG, OSP, Immersion Tin, ENEPIG, HAL) with excellent reliability of the surface treatment layer.

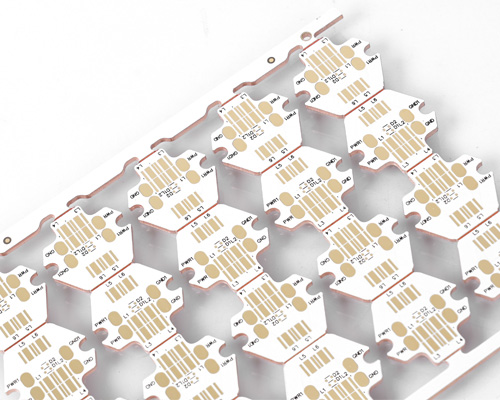

- Different structures can be made according to different design needs of LED. (Such as copper bump, copper concave block).

| SinkPAD Board (SinkPAD PCB) Capability | |

|

Base material: Copper core: 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.5mm Thermal Conductivity: 400 W/m.K. Board Thickness: 1.0 mm~2.0mm(0.04"~0.08") Copper thickness: 0.5 OZ, 1.0 OZ, 2OZ, (specially 3-10 OZ) Outline: Routing, punching, V-Cut Soldermask: White/Black/Blue/Green/Red Oil Legend/Silkscreen Color: Black/White/Yellow Surface finishing: Immersion Gold, ENEPIG, Immersion Tin, OSP Max Panel size: 600*500mm(23.62"*19.68") Packing: Vacuum/Plastic bag Samples L/T: 1.5~2.5 weeks MP L/T: 2.5~3.5 weeks |

|

Click here to see the manufacturing process of SinkPAD Board.

Customers’ special requirements for any type of SinkPAD is welcoming. Please contact EBest Circuit (Best Technology) today send your request for SinkPAD Board(SinkPAD PCB).