|

Just like FR4 PCB, we can also make boards with more than 2 layers of traces and we named it "Multi Layers MCPCB". The structure is similar with FR4 Multi Layers, but it much more complex to make. You can populated more components on the boards, put signal and ground layer into seperated layers, to achieve better performance in electrical performance. Compared with normal FR4, this sturcture need more technology and experience on laminating of more than two layers together with metal core and the cost is much higher than 2 layers MCPCB or double sided MCPCB. |

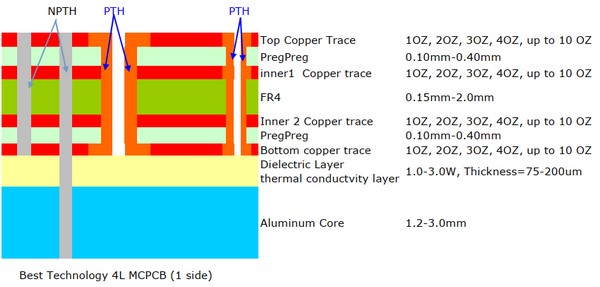

Structure of Multi Layers MCPCB |

|

| Capability of Multi Layers MCPCB |

|

| Please click here for immediate quotation online Please contact us for more information about the Multi layers MCPCB. |

ISimply drop your email or phone number in the contact form, and we'll promptly provide you with a quotation.