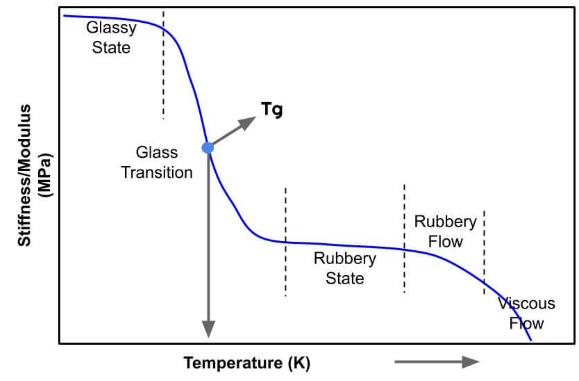

Tg means Glass Transition Temperature. As flammability of printed circuit board (PCB) is V-0 (UL 94-V0), so if the temperature exceeds designated Tg value, the board will changed from glassy state to rubbery state and then the function of PCB will be affected.

What Is a High Tg PCB?Tg means Glass Transition Temperature. A high Tg PCB is a circuit board made from materials with a Tg above 170°C. Standard FR4 materials have a Tg of around 130–140°C, but high Tg PCBs use materials that can withstand higher temperatures. As flammability of printed circuit board (PCB) is V-0 (UL 94-V0), so if the temperature exceeds designated Tg value, the board will change from glassy state to rubbery state and then the function of PCB will be affected.

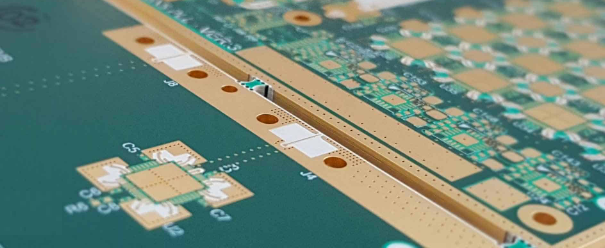

These PCBs maintain stability in high-power electronics, automotive systems, and industrial applications where excessive heat is generated. 170Tg raw material is also popular in LED industry, because heat dissipation of LED is higher than normal electronic components, and same structure of FR4 board is much cheaper than that of MCPCB or Ceramic board. The normal Tg value of MCPCB is the same as normal FR4 PCB as 130-140C, and customer can also ask for high TG (170-180C) for MCPCB, but the thermal conductivity can only be (0.3-0.4W/m.k).

If printed circuit board working temperature is higher than 170/180C, such as 200C, 280C, or even higher, then you'd better use Ceramic board which can go through -55~880C.

A higher Tg indicates better thermal stability and mechanical strength. When the temperature of a PCB exceeds its Tg, the board softens, leading to deformation and performance issues. A high Tg PCB can endure extreme temperatures without significant expansion or warping, improving the reliability and lifespan of electronic devices.

If working temperature of your product is higher than normal (130-140C), then have to use high Tg material which is > 170C. and popular PCB high value are 170C, 175C, and 180C. Normally the PCB Tg value should be at least 10-20C higher than working temperature of product. If you 130TG board, working temperature will be lower than 110C; if use 170 high TG board, then maximum working temperature should be lower than 150C. If you would like to know the difference between Tg 130 & Tg 170, please continue to read: Tg 130 VS Tg 170.

What is the Tg value of FR-4?Tg value is the most common grade index used to divide the FR-4 substrate, and it is generally believed that the higher the Tg value, the higher the reliability of the material.

The FR-4 substrate is divided into high, medium and low grades:

l Low Tg FR-4: Tg value is about 135℃

l Medium Tg FR-4: Tg value is about 150℃

l High Tg FR-4: Tg value is about 170℃

If there are more times of laminating, multiply PCB layers, high soldering temperature (≥230oC), high working temperature (≥100 oC), and large soldering thermal stress (such as wave soldering), high Tg material should be selected.

What Is the Difference Between Tg and Td PCB?Tg and Td are two critical thermal properties of PCB materials, but they serve different purposes in determining a board’s reliability under heat stress. Tg refers to the temperature at which the PCB material transitions from a rigid state to a softened, rubber-like state. When the PCB operates above this temperature, it may experience increased expansion, leading to mechanical instability and potential electrical failures. High Tg materials are preferred for applications requiring heat resistance and dimensional stability.

On the other hand, Td (Decomposition Temperature) is the temperature at which the PCB material begins to chemically decompose. Unlike Tg, where changes are reversible once the temperature drops, decomposition at Td is irreversible, causing material breakdown, loss of mechanical properties, and circuit failure. A higher Td value means the material can withstand extreme temperatures longer without degrading, which is crucial for applications exposed to prolonged heat or soldering processes.

Another key difference is that Tg primarily affects mechanical performance, while Td determines thermal durability. A PCB operating slightly above its Tg may expand but still function, whereas exceeding its Td results in permanent damage. For high-reliability applications, selecting materials with both a high Tg and a high Td ensures that the PCB can handle extreme conditions without warping or breaking down.

If working temperature of your product is higher than normal (130-140C), then have to use high Tg material which is > 170C. and popular PCB high value are 170C, 175C, and 180C. Normally the PCB Tg value should be at least 10-20C higher than working temperature of product. If you 130TG board, working temperature will be lower than 110C; if use 170 high TG board, then maximum working temperature should be lower than 150C.

If you would like to know the difference between Tg 130 & Tg 170, please continue to read: Tg 130 VS Tg 170.

In addition, in order to make customers to understand more information about high Tg materials, we also listed some specifications of Tg 150 & Tg 170, for further information,read now: Tg 150 VS Tg 170.

Here are some popular High Tg board raw material in market:

S1170 & S1000-2: SYL (Shengyi Technology);

FR406, FR408, IS410 & DS370HR: Isola

MCL-E-679: Hitachi;

Also there're a lot of different hi-tg material not listed here, different country, different company prefer using different material. Please view datasheet for each of them to choose most suitable material for you. If without special notice, normally we will use S1170 from SYL.

170Tg raw material is also popular in LED industry, because heat dissipation of LED is higher than normal electronic components, and same structure of FR4 board is much cheaper than that of MCPCB or Ceramic board. The normal Tg value of MCPCB is the same as normal FR4 PCB as 130-140C, and customer can also ask for high TG (170-180C) for MCPCB, but the thermal conductivity can only be (0.3-0.4W/m.k).

If printed circuit board working temperature is higher than 170/180C, such as 200C, 280C, or even higher, then you'd better use Ceramic board which can go through -55~880C.

Several manufacturers produce high Tg PCB materials with improved thermal stability and mechanical properties. These materials are widely used in automotive, aerospace, industrial controls, and power electronics. Some widely used options include:

l SYL (Shengyi Technology): S1170 & S1000-2

l ISOLA: FR406, FR408, IS410 & DS370HR

l Hitachi: MCL-E-679

l Rogers: RO4000 Series

A high Tg FR4 datasheet includes details about:

Tg value – Typically 170–180°C.

Thermal expansion (CTE) – Lower values mean better stability under heat.

Dielectric constant – Important for signal integrity in high-speed applications.

Flammability rating – Most high Tg PCBs meet UL94 V-0 standards.

For specific datasheet of high Tg materials, please download:

Download (PDF) S1170 Download (PDF) S1000-2 Download (PDF) FR406

Download (PDF) FR408

Download (PDF) IS410

Download (PDF) DS370HR

Download (PDF) N4000-6

Download (PDF) N4000-11

Download (PDF) Rogers 4350B

Also there're a lot of different high-Tg material not listed here, different country, different company prefer using different material. If you are not sure about what material you should specify, ask your PCB vendor or click here High Tg PCB to more information about high Tg products. The engineers from Best Technology are highly qualified and experienced, we can handle any complex PCB designs, and know both our PCB process & Capability and customers’ special requirements of PCB.

l Better Thermal Stability – Withstand high temperatures without deformation.

l Lower Coefficient of Thermal Expansion (CTE) – Reduces stress on components and solder joints.

l Improved Mechanical Strength – Ensures dimensional stability under thermal cycling.

l Enhanced Reliability – Suitable for harsh environments, including aerospace and industrial electronics.

l Dimension Stability - The dimension of the high Tg material changes little under high temperature and humid conditions, which can ensure the dimensional stability of the circuit board and reduce the error caused by environmental changes.

If you are looking for a trusted high Tg FR4 PCB manufacturer, please do not miss Best Technology. As an experienced PCB manufacturer in China, Best Technology specializes in manufacturing high Tg PCBs with a focus on quality, customization, and fast delivery. Our advantages including:

l Over 18 years of experience in high-performance PCB manufacturing.

l Custom high Tg PCB designs for industries such as automotive, medical, and telecom.

l Fast turnaround times for prototyping and mass production.

l Strict quality control processes, ensuring every PCB meets industry standards.

l Quick-turn high Tg PCB prototypes for testing and validation.

l Flexible order volumes, from small batches to large-scale production.

l Expert support to help select the right high Tg material for specific needs.

l China & Vietnam locally factory

l DDP & DDU quotation to avoid high tariff.

ISimply drop your email or phone number in the contact form, and we'll promptly provide you with a quotation.