|

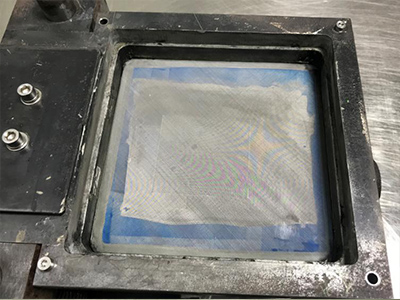

In fact, the process of laser drilling/scribing and stencil making can be done at the same time, as they’re belonging to different production workshop. The picture below is the front side of the stencil (It has been already installed on the manual printing table)

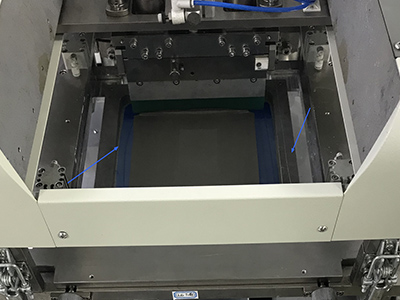

The stencil is installed on the printer working table and is ready for printing.

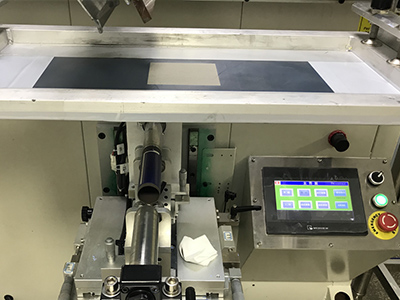

The size and the outline of the stencil will be different if it is used on the automatic or semi-automatic printing machine,.  The rectangular stencil is used to print the cylindrical substrate.

Now let’s move to the next step Conductive ink preparation . If you have any questions about the last step, please back to the Blackening spot removing after laser drilling |