|

The resistance ink can be printed after the conductor circuit was made. According to the different resistivity, only use the same value ink will be printed at a time. If there are many different resistivities, resistor needs to be made by different printing times. But before printing, the resistors should be dried after printing. It is not required to go through the high temperature fire oven every time, only need to be done at the last printing time. If you are still not clear the last step, please kindly to check here: Spreading, drying and over the firing oven , so that ink can be combined with ceramic substrate. The accuracy, electrical stability and solderability of the thick film resistor are related to the quality of thick film silkscreen. The products can not be used if there is a slight change in the thickness of the ink film. Therefore, the thickness uniformity of the thick film resistor will affect the rate of the product directly. The common thick film resistor is a cube that thickness is about 20 μm. If the thickness do not change, then the resistance value of the resistor can be determined by the ratio of length to width. The length-width ratio of the thick film resistor is range from 1:10 to 10:1. If resistor was made by with the same resistivity, the surface resistance can only be changed in the range of 10~1/10. If you would like to get the resistance value beyond this range, you have to change the ink with different resistivity. Resistor trimming by laser

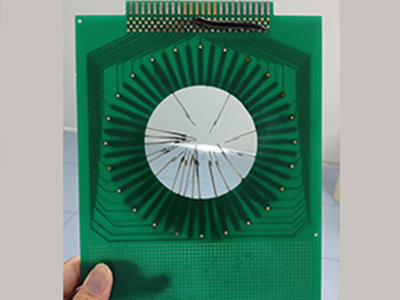

The jig board for adjusting the negative value is needed to be customized according to the circuit. The probe is fixed on the PCB based on the position of the resistor and it needs to be replaced at regular intervals. In a word,different boards should use different jigs.

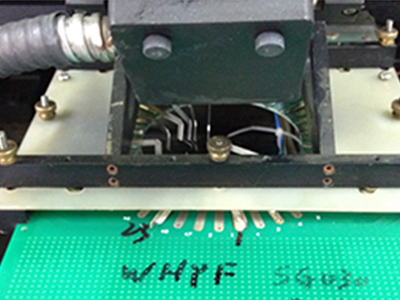

The jig board is inserted into the laser resistor trimming instrument.

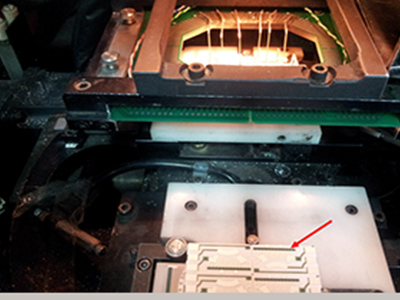

The laser resistor trimming instrument is operating.(Its principle is to measure the value of the resistor by two probes. According to the physical knowledge, the longer the conductor is, the larger the resistance will be, you can cut at a position that you want on the resistor. In this way, you can get the resistance value as you like. Generally, the initial value of printed resistor will be smaller than the desired one. If you want 100 ohm, the result may be 80 ohm. As you have already adjusted the resistance value to 100 Ohm after laser cutting, you can see the obvious laser cutting marks on the resistor.)

After we finished Printing resistance ink and laser resistor trimming, then we can move to Printing glass glaze to protect the circuit |