|

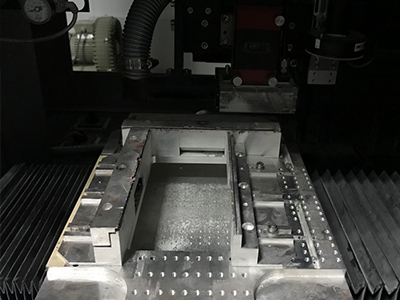

After the raw material is prepared, then the designers are able to drill and cut the outline. Now both the drilling technology and the outline cutting are using laser machine. But the laser energy is different, such as cold light source (UV light), carbon dioxide (CO2), fiber cutting and so on, so different laser machine will be used according to different condition such as drill hole size, substrate dimension, surface smooth, etc. CO2 laser machine for outline cutting and drilling (there’s no substrate on the working table).

CO2 laser is processing (The picture as below is drilling. Before drilling, a protective material layer will be add on the ceramic substrate to avoid the blackening at the edge of the hole during CO2 laser processing and to eliminate the spot of the laser to form a black spot on the surface of the ceramic substrate, or keep the surface clean.)

After that, let’s move to the fabrication process of Blackening spot removing after laser drilling About the raw material preparation, please read the raw material preparation if you have any questions. |