2) Produce both trace layer and copper core layer separately.

A. As of trace layer, it’ll be manufactured according to normal FR4 PCB, and raw material can be FR4 and BT (Bismakeimide-Triazine), but BT material is more commonly used. You can see more on PCB manufacturing process.

Normally it’s single copper trace layer on that trace layer. But we also have some customers like to design two copper trace layers. That’s also no problem.

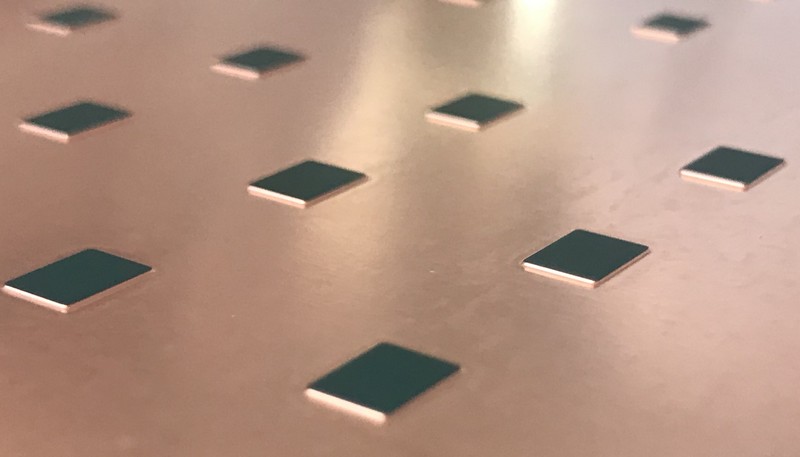

Here are pictures of finished trace layer. (one copper trace layer)

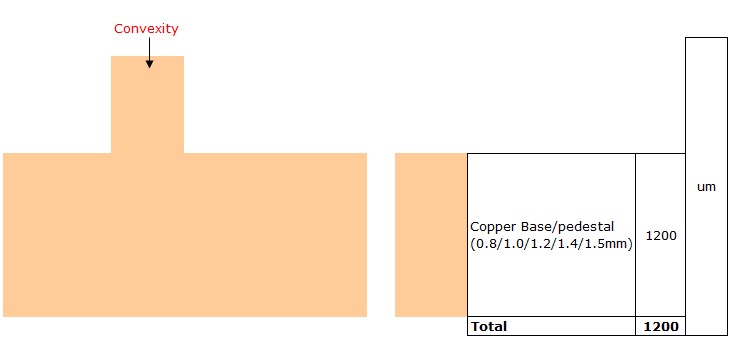

B. Regarding the copper core layer, that’ll be a little complicated than normal.

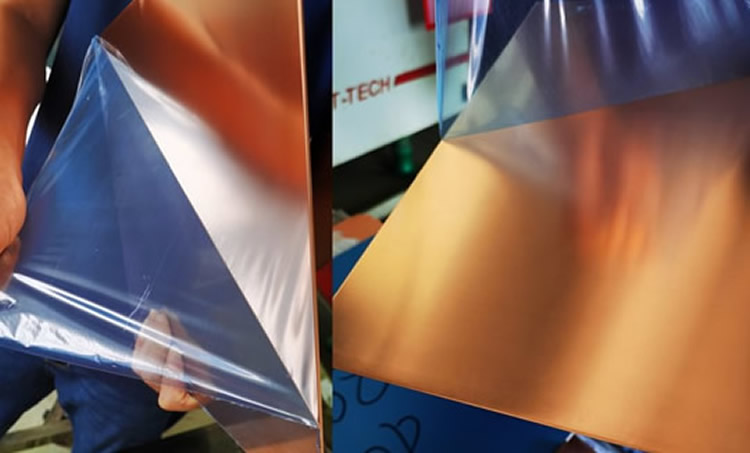

b1. Normally the thickness of copper core/substrate is 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.6mm, 2.0mm. And there’re protection film (blue color) on both sides. We will remove that protection film after raw material cutting, before convexity making, so that copper can be etched.

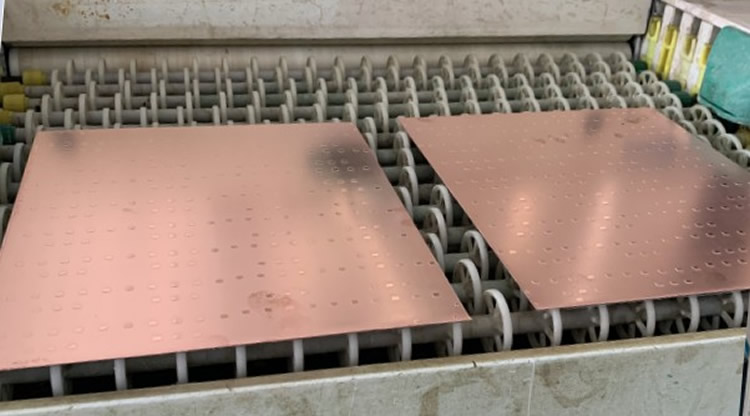

(copper core before grinding) (copper core come out from grinding m/c)

(copper core before grinding) (copper core come out from grinding m/c)

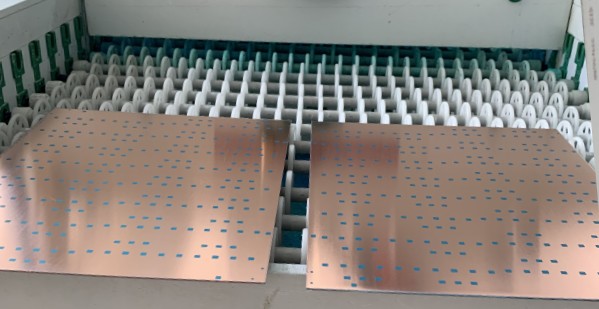

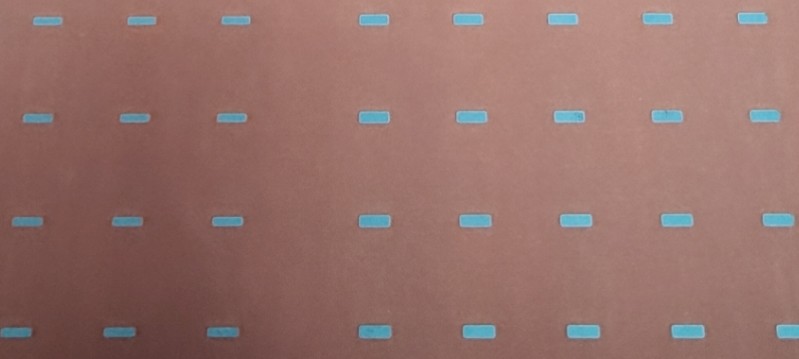

b2. We will add one extra layer of film (normally blue color, and will refer to blue film hereafter) on whole area copper core, and after developing & etching, only selected area of blue film will be kept and other area will be removed away. In fact, the area of blue film will be the place heatsink PAD will be.

(copper printed with wet blue film) (printing wet blue film on copper core)

(copper printed with wet blue film) (printing wet blue film on copper core)

If that is a single layer board, then the blue film will on the top side of copper core and there’ll be a transparent film (refer to transparent film) on bottom side of copper, to protect bottom copper from etching.

And of course, you can design two layers of trace circuit on the same side, then we will name it as 2L SinkPAD Board, and manufacturing process is the same as 2L FR4 PCB.If there’re SinkPAD on both sides, then we will put blue film on both top and bottom side of copper core.

(copper core with blue film on convexity, before etching)

(copper core with blue film on convexity, before etching)

(copper core with selected area covered with blue film)

(copper core with selected area covered with blue film)

And of course, you can put two layers of trace circuit on both top and bottom sides, then to make 4 Layers double sided SinkPAD Board.

b3. Etching the copper layer, the copper in the area without the protection of blue film or transparent film will be etched away and depth will be 0.20mm-0.25mm. Only the copper in the area with blue film keep the unchanged and that area we normally named it as convexity.

(convexity coming out, still with blue film)

(convexity coming out, still with blue film)

(convexity coming out, without blue film)

(convexity coming out, without blue film)

Return to main manufacturing process See next step: Laminate trace layer and copper core layer together.