|

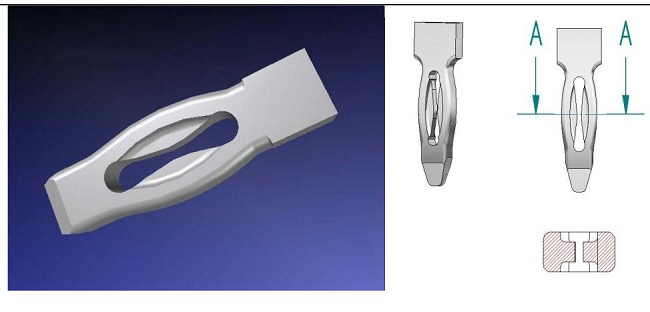

There are different types of press-fit connectors, including those with solid pins (which don’t contort during insertion) and compliant pins (which compress or “comply” during insertion). Solid press-fit technology came first, but designers and manufacturers were concerned about the board damage caused by solid press-fit contacts. To combat the problem, compliant press-fit technology was developed. Today, compliant pins are generally preferred because they make less demands on the PCB, require less force during the insertion process, and produce more reliable results (with less damage). Both types are still currently used, but compliant technology tends to be more convenient and effective (and thus, more popular). Compliant press-fit technology improved upon solid press-fit methods, but there is still a risk of damaging PCBs and backplanes due to the high force needed for proper insertion. Bi-spring power press-fit contacts reduce these insertion forces. They also add mounting screws for increased stability during shock and vibration environments (so the movement and stress caused by coupling, uncoupling, and shaky environments won’t transfer to the PCBs or backplanes). Plus, some bi-spring power press-fit connectors eliminate the need for costly press-in equipment. When they’re used properly, press-fit terminations offer strong and reliable service, whether they’re employed in a benign application or a harsh one. Normally the pin is made of a copper alloy with nickel plating and a tin finish, so recommend PCB surface finishing will be HAL.

|