|

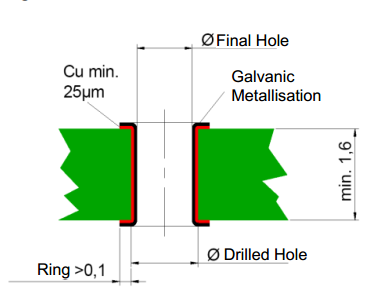

According to the IEC 60352-5 standard, there are some requirements referring to the Plated Through Hole of the PCB. On the one hand this ensures the proper functioning on the other hand BEST TECHNOLOGY did all qualification tests with these values. The qualification tests are done on standard FR4 PCBs and on a surface finish of immersion tin (I-Sn) and electroless nickel immersion gold (ENIG). Printed board material meets the requirements of IEC 61249-2-7. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The tin finish fulfilled all the requirements. The gold finish showed lower press out forces that not complied with the mechanical requirements of the stress relief part. Never the less modules with Press-fit pins can be used with PCBs having a ENIG finish but a re-use of the PCB in case of service is not possible. The module pins have to be soldered when the PCB have to be used a second time.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The following table shows the specification of PTH for immersion tin plating:

The following table shows the specification of PTH for electroless nickel immersion gold plating:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||