SinkPAD Board Manufacturing Process

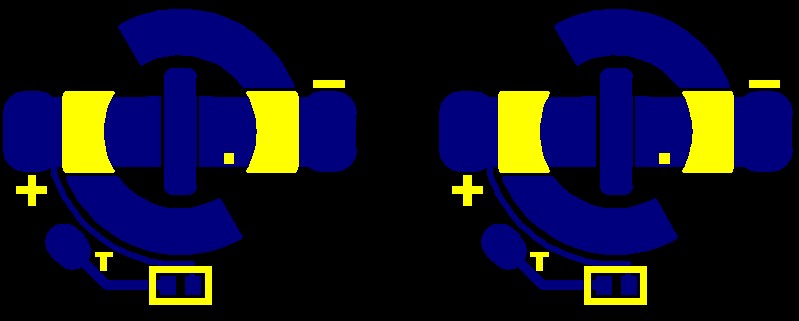

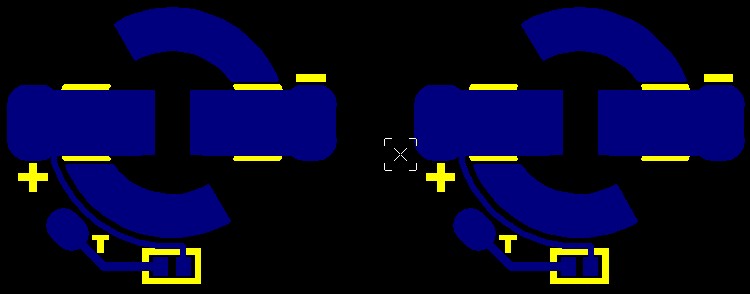

First of all, we need to understand there’s two major parts of SinkPAD board: Top trace layer and copper core/substrate. Then you can see basic manufacturing process of SinkPAD board bellowing:

1) Prepare the manufacturing files.

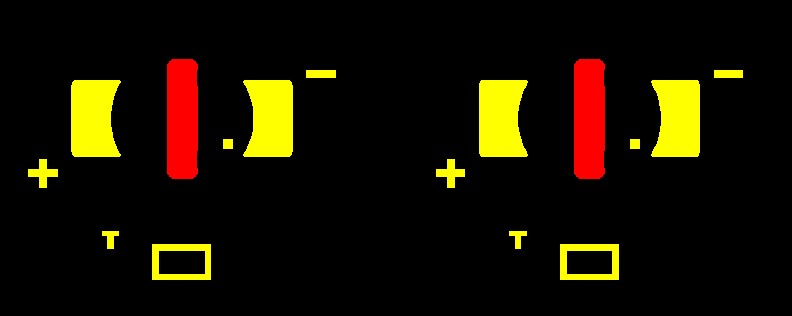

Major thing is to separate the copper core and trace, from one Gerber layer, to two different layers. On one layer, there’s only trace but without center heatsink PAD of LED and that layer will be named as trace layer; and on another layer, there’s only heatsink PAD, and that layer will be named as copper core layer.

Original Gerber File (Top Layer + Top Silkscreen)

Revised Gerber file (Top Layer)

New Added Copper layer (convexity on copper core)

Final Revised Gerber File

Return to main manufacturing process See next step: Produce both trace layer and copper core layer separately.